HEAT EXCHANGER APPARATUS AND OTHER DEVICES FOR CONTROLLING TEMPERATURE OF SUBSTRATE OR OTHER LAYERS IN CULTIVATING HORTICULTURAL PRODUCTS, AND ESPECIALLY MUSHROOMS AND AERIAL MYCELIA, SYSTEMS UTILIZING SUCH HEAT EXCHANGER APPARATUS, INFLATABLE BLADDER FOR PLACEMENT ONTO SUBSTRATE, AND METHODS OF USING SAME

FIELD OF TECHNOLOGY

[0001] The field of technology relates to heat exchangers and other devices for controlling the temperature of substrates for cultivating horticultural products, such as for example for controlling the temperature of soil, compost, or other nutritional materials which support the growth of one or more desired crops, e.g. plants, mushrooms, or mycelia.

BACKGROUND

[0002] Desirably horticultural products, such as ornamental plant cuttings, seeds, mushrooms (the “fruiting bodies” of certain fungi), fruit crop seedlings, vegetable crop seedlings, and mycelium (that is, the vegetative, root-like growth structures of certain fungi characterized by extended filaments known as hyphae), are often cultivated in a controlled environment, e.g. in indoor facilities such as greenhouses, growth environments, growth chambers and bioreactors, where growing conditions such as lighting, nutrients, humidity levels, airborne mist levels, gaseous atmospheres, and temperatures can be monitored and carefully regulated. Such products are frequently grown on or in a layer of nutrient-providing substrate (or “growth substrate”), such as soil, sawdust, straw, compost, or other lignocellulosic material, which may be supported by carrier structures, such as shelves, racks, tables, nets (on or off shelves), plates (on or off shelves), trays (on or off shelves), or beds (on or independent of shelves), which carrier structures are frequently arranged in the form of a rack, or shelves on multiple levels of a rack (which rack is frequently in a vertical configuration) in a growth environment. Such carrier structures are most frequently aligned in columnar and/or row configurations for ease of viewing of the horticultural crops, and tending to the growing plant or fungal materials. Through certain solid-state fermentation systems, the substrate (such as for mushrooms and/or mycelium) may additionally be first placed upon a carrier support (e.g. shelves in a rack, or on a table), housed in a growth environment, sterilized or pasteurized in that same growth environment location, inoculated with fungal spawn also in that same growth environment, optionally allowed to colonize mycelium also within that same growth environment, and allowed to eventually grow both withinn the substrate and also “aerially” above and away from the growth substrate within that same growth environment. In the case of mycelium, the mature mycelium may then be finally harvested and/or rendered biologically inert, in some instances in that same growth environment, by being exposed to heat, such as drying heat. Such heat may be delivered from the growth environment heating, ventilation, and air-conditioning system (aka HVAC), or via heat exchangers which heat the substrate.

[0003] The optimal temperature, humidity, and nutrient composition of a substrate may vary in time over the desired product ‘s lifecycle, depending for instance on the cultivation phase of the target product. For example, relatively mild substrate conditions and/or available moisture for root formation, may be desirable in a growing phase to promote desired product germination and growth, while in a harvesting phase the temperature of the substrate may be desirably either increased to reduce the humidity of the substrate, so that the harvesting process is facilitated, or reduced, so as to slow product growth. Controlling the temperature of the substrate may also be beneficial for other reasons, for example, to optimize the growing conditions based on the type of horticultural product, the type of substrate, the nutrient uptake, seasonal aspects, the desired growth stage of the product, and the desirability for maintaining an overall stasis or static condition of the living but immature product organism, which is to be eventually grown into a mature product, such as a mature aerial mycelium without the presence of fruiting bodies. As previously noted, the temperature of the substrate may be increased in order to also dry the grown organism, such as for example mature aerial mycelium.

[0004] Some desired crops, such as mycelium, may themselves generate a certain level of heat during a growth phase, and it may be desirable to reduce that level of heat in the substrate and/or surrounding environment over time, such that the growing material does not become overheated. Similarly, temperatures in a greenhouse may become extreme and it may be desirable to cool down one or both the temperature of the ambient air in the greenhouse and the substrate temperature, such as through traditional fan and HVAC systems, but also by lowering the temperature of the growing medium or the substrate supporting the growing organism.

[0005] As noted previously, in certain arrangements for cultivating horticultural products, the substrate is supported on a carrier structure, such as the carrier plate, a net or web, a bed, a tray, a table, a rack, shelves on a rack etc., which has a certain carrier surface area for carrying the growth substrate. Because of the weight of the substrate and the increasing weight of the horticultural products growing on the substrate, the carrier structure may require a certain thickness and/or rigidity for providing sufficient strength and stiffness, e.g. bending stiffness, across the surface area to support the substrate and horticultural products, without damage or excessive deformation to the carrier structure, e.g. such as when the substrate is suspended in a rack, table, or other type of similar support. This may be especially important if a rack itself consists of open-railed shelving or tables comprised of spaced-apart bars, rails, or wires, or alternatively, the carrier structure includes an open netting or web-like sheet. Certain open carrier structures may be beneficial for the circulation of air in and around the growing organisms.

[0006] In the process of raising plants from seeds it has been a practice of growers to provide supplemental, gentle heat through the use of warming pads, mats, or trays placed under recently planted seeds or transplanted seedlings to facilitate their germination, or for recently geminated seedlings, to facilitate early growth and root formation, each by the provision of gentle, controlled warming. In certain instances, such heating mats may also be used to provide desirable environmental static conditions to warmth-loving plants, such as succulents. However, such heating mats are most frequently made from thin layers of insulating PVC, which contain a relatively fragile electrical circuit for providing the desired gentle warmth, and which use is discontinued upon the attainment of a certain stage of growth (that is the mats are shut off when the seeds have either germinated or the seedlings have reached a certain height and/or maturity). They are not designed to support much weight (as they typically support relatively shallow seed trays for a relatively short period of time), or to transfer continuous heat through relatively large masses of substrate materials. Furthermore, they do not provide a substrate with the ability to proactively cool down (other than by shutting off an activated heating element in the mat), if such is needed for the raising of certain types of crops. Their limited structural support features therefore makes them impractical for the heating of certain horticultural crop substrates requiring relatively heavy and thick, or multiple substrate layers (such as wood-based particles typically used for mushrooms or mycelium), and which are also exposed to the relatively heavy weight created by accompanying moisture, nutrients, and plant or fungi mass material.

[0007] Greater strength and stiffness for supporting a substrate (or multiple layers thereof) and accompanying horticultural products of a commercial grower are therefore necessary for certain horticultural products, such as mushrooms and mycelium, when a heat exchanger function is also desired (that is including the cooling feature as well). Such strength and stiffness, while not provided by the traditional heating mats, may be provided by enclosing or sandwiching a heat exchanger within a rigid carrier structure, e.g. by having the heat exchanger placed inside a carrier frame, or between a carrier plate and a substrate supporting plate. Alternatively, temperature regulating devices may be constructed to include fixed fluid conduit structures (such as a closed pipe system on a rack or in the rack itself), for transporting temperature-affecting fluids, such as air or liquid to shelves on racks. Such are described for instance in NL1035600 and NL8201720. However, upon heating the substrate, the carrier structure may act as a heat sink, causing part of the energy from the heat exchanger and/or the substrate to be transferred into the carrier structure or rack. Conversely, when the heat exchanger is arranged for cooling the substrate, part of the heat stored in the carrier structure may be transferred into the heat exchanger and/or into the substrate. In such cases, the typically metal carrier structure thus also acts as an undesirable heat source. Furthermore, the relatively fixed heat exchanger designs are not adaptable to accommodate variable and established grower rack designs/arrangements already in place, and all too common in the agricultural field. Nor are they physically flexible in structure, so as to be easily assembled, disassembled, and later reassembled to be used with a different growth platform design. They also may require a significant capital investment that may be prohibitive for certain farmers. It would therefore be desirable to have heat exchanger units which could be easily moved, are physically flexible in structure to allow their use with various, already utilized growth rack designs, and which are fashioned from materials that would not be cost prohibitive.

[0008] Examples of other more rigid rack structures are described in European Patent Publication EP2564687 to Christiaens et al., which comprises a rack bottom, a carrier which is supported with respect to the rack bottom for the substrate, and a heat exchanger to heat and/or cool the substrate on the carrier. Although this makes it possible to influence the temperature of the substrate to a certain degree, the controllability of the substrate temperature may still be challenging, e.g. due to the internal arrangement of components and materials used, which affects the heat transfer properties of the system as a whole. As a result, the energy efficiency of these rack systems, as well as their horticultural yield may not be optimal.

[0009] Still further designs for heat exchangers to be used for supporting the growth of horticultural products continue to be proposed, so as to address continuing issues of heat efficiency and substrate support. For example, another heat exchanger design is described in International Publication WO2023/229459 to Christiaens. Such design is described to improve controllability of the temperature of a horticultural product substrate. In particular, the reference describes the heat exchange surface as forming the carrier structure surface, which in turn directly contacts the substrate, thereby directly influencing the temperature of the substrate with reduced thermal loss during the transfer of heat between the heat exchanger and the substrate. The heat exchanger is described as potentially serving as the supportive structure itself, which may eliminate the need or desire for including a separate rack structure (which may also reduce heat or cooling loss). The described design includes the potential inclusion of an extendible section to extend or shorten in the plane of the overall carrier plate. However, as with previously described heat exchanger configurations, this design poses potential adaptability challenges for established growers having a variety of existing shelf or rack designs, and requires new infrastructure spend in order to utilize it. It would therefore be desirable to have a heat exchanger capable of providing the flexibility for different growth rack platform design use, and at limited investment costs.

[0010] In some examples of current heat exchanger designs, drying heat may also be provided by heated substrate material as a result of a fixed heat exchanger apparatus. Such mycelium growth systems are, for example, described in International Patent Application WO2022/265498 to Rademakers. However, as with previously described configurations, such designs lack the physical flexibility to be assembled, disassembled, and later reassembled easily, for use with any number of differing growth rack systems. Furthermore, such systems require initial capital investment costs which may be significant for certain farmers having only a limited need for such devices based on their target crops.

[0011] While the previously described systems may include cooling aspects, such as to draw away heat generated by particular crops, or to lower temperature of substrates in response to other environmental conditions, such as excessive heat in greenhouses, such as that design described in FR2554315, there is still a need for flexible heat exchanger designs which can be easily manipulated to accommodate both the heating and cooling needs of horticultural products stored on varying design growth rack structures, and which do not require significant initial investments for use.

[0012] Finally, with respect to crops which benefit from the use of a heat exchangers during at least one phase of the crop’s lifecycle, such as during seed germination, or during plant or mushroom growth, the used substrate is either discarded entirely or relegated to the compost bin. The previously described heat exchangers do not impart other features of value to the heated or cooled substrates that would enable the depleted substrate itself to later be used as an end product offering separate value. It would therefore be desirable for a heat exchanger to offer the flexibility to be used in multiple growth rack platforms, and which could offer flexibility to be used to provide a secondary use for the previously heated/cooled substrate, apart from being relegated to a compost bin.

[0013] It is therefore an object of the invention to provide a heat exchanger or heat exchanger structure, with improved controllability of the temperature of a horticultural product substrate, regardless of an established supporting growth rack system. It is a further object of the invention to provide a heat exchanger, which offers flexibility to be easily assembled or installed, and disassembled or uninstalled for later use at another time and location as needed. It is still a further object of the invention to provide a heat exchanger with relatively lower start-up costs, based on heat exchanger design elements. It is still yet a further object of the invention to provide a heat exchanger which is multifunctional, in that it offers both heating and cooling features, as well as the potential for moisture/nutrient addition to a targeted substrate. It is still a further object of the invention to provide a heat exchanger, which allows for the support of relatively significant substrate weight (and associated weights of moisture and growing crop mass). It is still a further object of the invention to provide a heat exchanger, which use incorporates other functionality into a depleted substrate, rather than supporting the singular use as compost. Finally, it is still a further object of a heat exchanger structure, which itself could be used for a secondary purpose in the growth of horticultural products, such as to promote secondary or supplemental growth of additional horticultural products which would not otherwise form, without the presence of the heat exchanger structure.

Summary

[0014] In one embodiment, a heat exchanger apparatus for temperature control of a growth layer such as a substrate or casing layer, for cultivating horticultural products, has a structure including an inflatable bladder having an inflatable bladder main body. The inflatable bladder main body has at least one inflatable bladder main body exterior wall which defines an interior space within the inflatable bladder main body. The at least one inflatable bladder main body exterior wall is inflatable by a temperature-controlled fluid introduced into the interior space, such that its outer dimensions expand upon inflation by the temperature-controlled fluid, and which inflatable bladder main body upon expansion of the outer dimensions, is capable of supporting the weight of a growth layer such as a substrate, a casing layer, an aerial mycelium, or a combination thereof placed or grown respectively upon the inflatable bladder main body, either directly or indirectly upon the inflatable bladder main body, without the inflatable bladder main body exterior wall experiencing rupture. The inflatable bladder main body is capable of retaining the temperature-controlled fluid within the interior space defined by the at least one exterior wall, unless intentionally released to the growth layer, such as the substrate, casing layer, aerial mycelium layer or combination thereof, which are supported by the inflatable bladder main body. The inflatable bladder main body is capable of either imparting heat, or absorbing heat through the at least one inflatable bladder main body exterior wall to or from material layers adjacent the inflatable bladder main body. The apparatus also includes a feeder conduit, for feeding temperature-controlled fluid to the inflatable bladder main body interior space.

[0015] In an alternative embodiment, the inflatable bladder main body includes multiple chambers. In a further alternative embodiment, the inflatable bladder main body includes multiple materials on its at least one exterior wall. In still another alternative embodiment, the inflatable bladder includes elastic materials on its exterior wall. In still another alternative embodiment, the inflatable bladder main body includes metallic material on its at least one exterior wall. In still another alternative embodiment, the noted metallic material is selected from the group consisting of metallic films, foils, plates, particles, fibers, filaments, and laminates thereof. In still another alternative embodiment, the inflatable bladder main body includes extensible or repetitively extensible material along its one or more exterior wall. In still another alternative embodiment, the noted extensible or repetitively extensible material is selected from the group consisting of foldable, kinked or gathered materials, overlayed, nonwoven or woven materials, and stretchable or elastic materials. In still another alternative embodiment, the inflatable bladder main body includes extensible material along at least a portion of its one or more exterior walls. In still another alternative embodiment, the inflatable bladder main body exterior wall includes exterior wall pores or openings which are capable of selectively releasing fluid to the growth layer, substrate, casing layer, or growing aerial mycelium, and/or capable of allowing for the passage of mycelium hyphae. In still another alternative embodiment, the noted exterior wall pores of the inflatable bladder main body exterior wall includes controllable valves, one-way valves, soaker-type openings, or emitters. In still another alternative embodiment, the inflatable bladder main body includes at least two separate exterior walls, one of which primarily faces either the growth layer, substrate, casing layer or aerial mycelium in use. In still another alternative embodiment, the inflatable bladder exterior wall includes portions which are capable of conforming in profile shape to the overall profile shape of substrate particles contained within a substrate. In still another alternative embodiment, the inflatable bladder main body includes a first chamber that is inflatable, and a second chamber that is not inflatable. In still another alternative embodiment, the inflatable bladder main body includes an exterior wall shape which is capable of creating an indentation or surface texture in an adjacent substrate layer to which it comes in contact. In still another alternative embodiment, the noted indentation leaves a formed cavity in the substrate following use of said heat exchanger to heat or cool the substrate and grow horticultural products, that are selected from the group consisting of mushrooms and mycelia. In still another alternative embodiment, the noted temperature-controlled fluid is selected from either gas or liquid, alternatively either air or water. In still another alternative embodiment, the noted temperature-controlled air is selected from either growth environment ambient air that is exposed to the heat exchanger apparatus or air that has been cooled or heated to a temperature different from the growth environment ambient air. In still another alternative embodiment, the noted temperature-controlled liquid is selected from either water or oil. In still another alternative embodiment, the noted temperature-controlled water includes nutrients for providing said horticultural product with supplemental nutrition apart from nutrition contained in said substrate.

[0016] In still another alternative embodiment, the inflatable bladder main body includes at least two chambers, with a first chamber capable of raising the temperature of adjacent substrate material, and a second chamber capable of lowering the temperature of adjacent substrate material at the same time the first chamber is capable of raising the temperature of adjacent substrate material. In still another alternative embodiment, the inflatable bladder main body includes at least two different materials along at least one of its exterior walls, the at least two different materials exhibit two different levels of heat transfer or thermal conductivity. In still another alternative embodiment, at least one of the materials along at least one exterior wall is metallic. In yet another alternative embodiment, the materials along at least one exterior wall are either elastic, extensible, or expandable. In yet another alternative embodiment, the noted exterior wall is made from one or more materials selected from the group consisting of elastic polymer material, natural or synthetic rubber material, and extensible or expandable materials, which are extensible or expandable based either on chemical composition, or physical structure, alternatively woven or nonwoven construction. In yet another alternative embodiment, the noted extensible or expandable materials are selected from the group consisting of nonwoven materials, laminates of nonwoven materials and film materials, and film materials. In yet another alternative embodiment, the noted nonwoven materials are selected from the group consisting of meltblown, spunbond, and laminates of meltblown and spunbond materials.

[0017] In yet another alternative embodiment, the noted elastic or extensible material is adjacent at least one metallic material. In yet another alternative embodiment, the heat exchanger includes at least one heating element separated from the inflatable bladder main body interior space, which provides additional heat to the inflatable bladder, in addition to the heat provided to the inflatable bladder main body by the temperature-controlled fluid.

[0018] In still another alternative embodiment, the heat exchanger is connected via a feeder conduit to a circulating pump or fan, for circulating temperature-controlled fluid through the inflatable bladder main body. In yet another alternative embodiment, the feeder conduit comprises an elongated tubular structure connected to the main body of the inflatable bladder.

[0019] In yet another alternative embodiment, the feeder conduit comprises a connection integrally connected to the inflatable bladder main body. In yet another alternative embodiment, the feeder conduit is fashioned of a material different from the material comprising the main body of the inflatable bladder. In yet another alternative embodiment, the feeder conduit is fashioned of a material that is not expandable. In yet another alternative embodiment, the feeder conduit includes insulative material. In yet another alternative embodiment, the noted temperature-controlled fluid is fluid obtained from ambient fluids surrounding the inflatable bladder main body. In yet another alternative embodiment, the temperature-controlled fluid is ambient air surrounding the inflatable bladder main body. In yet another alternative embodiment, the temperature of the noted temperature-controlled fluid is independently controlled from ambient temperature surrounding the inflatable bladder main body. In yet another alternative embodiment, the temperature-controlled fluid is recirculated between more than one inflatable bladder main bodies.

[0020] In yet another alternative embodiment, the inflatable bladder main body includes at least two generally opposing exterior outer surfaces, formed of at least one exterior wall, one exterior outer surface facing the direction of substrate, and one exterior outer surface facing the direction of aerial mycelium, with the two exterior outer surfaces defining at least one open channel therebetween, through which mycelium hyphae may extend during growth. In yet another alternative embodiment, the inflatable bladder main body includes multiple open channels through which mycelium hyphae may extend during growth from one adjacent layer to another (from opposing sides of the inflatable bladder). In yet another alternative embodiment, the noted multiple open channels are arranged in an array across said inflatable bladder main body.

[0021] In yet another alternative embodiment, the noted at least one open channel is a continuous channel between said two exterior outer surfaces. In yet another alternative embodiment, the inflatable bladder includes one or more discrete inflatable members positioned adjacent a flexible connecting member.

[0022] In still another alternative embodiment, a method for influencing growth of a horticultural product, and in particular aerial mycelium in a growth environment, includes the steps of: providing a surrounding growth environment for the growth of a horticultural product, and in particular aerial mycelium, including at least one carrier structure; placing at least a horticultural product-seeded substrate, and in particular, a fungal-inoculated substrate upon or beneath a heat exchanger apparatus upon the carrier structure, the heat exchanger apparatus comprising an inflatable bladder, and the inflatable bladder having a main body, the main body having at least one main body exterior wall, which at least one inflatable bladder main body exterior wall defines an inflatable body interior space that is inflatable by a temperature-controlled fluid introduced into the interior space, such that the inflatable bladder main body outer dimensions expand upon inflation by the temperature-controlled fluid, and which inflatable bladder main body, upon expansion of the outer dimensions, is capable of supporting the weight of either a substrate, a casing layer, an aerial mycelium layer or a combination thereof placed or grown respectively upon the inflatable bladder main body, either directly or indirectly upon the inflatable bladder main body, without the inflatable bladder main body exterior wall rupture. The inflatable bladder main body being capable of retaining the temperature-controlled fluid within the interior space defined by at least one exterior wall, unless intentionally released to the substrate, casing layer, aerial mycelium layer or combination thereof, which are supported by the inflatable bladder main body. The inflatable bladder main body being capable of either imparting heat, or absorbing heat through the at least one main body exterior wall to or from materials adjacent the inflatable bladder main body. The heat exchanger apparatus also including a feeder conduit, for feeding temperature-controlled fluid to the inflatable bladder main body. The steps also include imparting growth conditions to the growth environment thereby allowing the horticultural product, and in particular, fungal inoculum, to grow into a horticultural product, and in particular, aerial mycelium; inflating the inflatable bladder main body with a temperature-controlled fluid to either provide heat or absorb heat from material adjacent the inflatable bladder main body; regulating the temperature-controlled fluid such that the temperature of the temperature-controlled fluid facilitates growth of a horticultural product, and in particular, mycelium in the growth environment.

[0023] In yet another alternative embodiment, the flow of the temperature-controlled fluid into the inflatable bladder main body is regulated by a controller or processor. In yet another alternative embodiment, the temperature-controlled fluid is circulated within the inflatable bladder main body via a circulating pump or fan. In yet another alternative embodiment, the temperature-controlled fluid is maintained at a temperature that is the same as the temperature of the surrounding growth environment. In yet another alternative embodiment, the temperature-controlled fluid is controlled to be a temperature different from the temperature of the surrounding growth environment. In still another alternative embodiment, the temperature-controlled fluid is either cooled or heated by a cooling or heating unit respectively.

[0024] In yet another alternative embodiment, the carrier structure is a rack including at least one shelf. In yet another alternative embodiment, the carrier structure is a rack including multiple shelves, each shelf supporting an inflatable bladder main body of a heat exchanger apparatus and inoculated substrate, with each heat exchanger inflatable bladder main body being independently controlled to monitor and control the temperature of the temperature-controlled fluid used to inflate each of the bladders’ main bodies. In yet another alternative embodiment, the heat exchanger apparatus inflatable bladders are temperature controlled to align with the particular growth levels of the mycelium contained on the shelves. In yet another alternative embodiment, a casing layer is provided adjacent either the substrate or the inflatable bladder main body. In yet another alternative embodiment, the inflatable bladder main body is provided with channels to thereby allow the growth of a horticultural product, and in particular, mycelium hyphae through the inflatable bladder main body from either the substrate or a casing layer. In still another alternative embodiment, the method includes a step of feeding fluid from the growth environment into the inflatable bladder main body. In another alternative embodiment, the method further includes the step of dispersing at least one of water, air, or nutrients from the inflatable bladder main body to the growing horticultural product, and in particular, mycelium. In yet another alternative embodiment, the method further includes the step of providing separate heating and cooling via the inflatable bladder main body. In another alternative embodiment the method further includes the steps of providing the inflatable bladder main body with a desirable exterior shape or texture, and establishing conditions within the growth environment to allow the formation of aerial mycelium, and then separating the aerial mycelium from the substrate, thereby producing a self-supporting composite substrate having an external shape or texture that is the negative shape of the desirable exterior shape or texture of the inflatable bladder main body.

[0025] In yet a further embodiment, the heat exchanger with inflatable bladder (e.g. main body at least) is disposable, given that it is made from generally lower cost materials and does not require much set-up. In a further alternative embodiment, the heat exchanger with inflatable bladder (e.g. main body at least) is of single or limited use, such that it can be assembled and used for a variety of design growth systems, and then disposed of. Such inflatable bladder allows the heat exchanger to be easily assembled, put into operation as needed, and then to be simply disassembled and either stored for later use, or disposed of. If such inflatable bladder is only extensible in one instance and not contractable, it may be desirable to only use it in one horticultural product growth operation. One benefit to such inflatable bladder construction is its adaptability, and the lack of need to provide significant accompanying structural redesigns or attachment mechanisms in order to use it on a variety of growth technology platforms. It does not require more permanent or semipermanent features to be attached to existing growth systems.

[0026] In still another alternative embodiment, the temperature-controlled fluid to be circulated through the inflatable bladder main body is air. In yet another alternative embodiment, the temperature-controlled fluid to be circulated through the inflatable bladder main body is ambient air from the growth environment. In still another alternative embodiment, the temperature-controlled fluid to be circulated through the inflatable bladder main body is water. In still another alternative embodiment, the temperature-controlled fluid to be circulated through the inflatable bladder main body is ambient water from somewhere else in the growth environment, such as for example, the water from the mist system.

[0027] In still another alternative embodiment, the heat exchanger inflatable bladder (e.g. main body) is manufactured from a nonwoven material, such as a nonwoven sheet material. In an alternative embodiment, the heat exchanger inflatable bladder (e.g. main body) is manufactured from a nonwoven material having a surface with holes ranging from between about 10 microns to 500 microns (e.g. at varying distributions of frequency). Such holes may be as a result of nonwoven sheet formation processes (such as the distance between fiber lay-down) or alternatively, via intentional perforation or needling actions. In another alternative embodiment, the heat exchanger inflatable bladder (e.g. main body) is manufactured from a woven material including holes along its surface, such as between about 10 microns 500 microns. In still another alternative embodiment, the heat exchanger inflatable bladder (e.g. main body) is manufactured from a plastic or polymeric film or membrane, with perforations, wherein the perforations are in one embodiment, of between about 1 micron to about 1 mm in diameter. In still a further alternative embodiment, the heat exchanger inflatable bladder (e.g. main body) is manufactured from an edible casing (as would be provided in edible sausage manufacturing processes), such that growing mycelium may penetrate through the material through digestion of hyphal tip extension. The edible casing may include a particular hole pattern that may also be found in edible casing materials. Alternatively, the edible casing may include a perforation arrangement in which the perforations may range in size from about 1 micron to about 1 mm in diameter.

[0028] In yet another alternative embodiment, the temperature-controlled fluid which is circulated in the heat exchanger inflatable bladder, and which transfers heat or cooling to an adjacent layer, may impact an adjacent layer such that it is either heated to cooled to a temperature between about 20 and 35 degrees C, alternatively to between about 27 and 30 degrees C. Such a temperature may be between about 0 and 5 degrees C, alternatively between about 1 and 3 degrees C greater than the surrounding air temperature. In one embodiment, the temperatures of the heat exchanger inflatable bladder are independently controlled from the temperatures of the surrounding air of the growth environment.

[0029] In yet another alternative embodiment, a heat exchanger apparatus system for regulating temperature of a substrate for cultivating horticultural products includes at least one heat exchanger apparatus having a structure including an inflatable bladder having a main body, the main body having at least one inflatable bladder main body exterior wall, defining an interior space, which at least one inflatable bladder main body exterior wall is inflatable by a temperature-controlled fluid such that its outer dimensions expand upon inflation by the temperature-controlled fluid, and which inflatable bladder main body upon expansion of the outer dimensions, is capable of supporting the weight of either a substrate, a casing layer, an aerial mycelium layer or a combination thereof placed or grown respectively upon the inflatable bladder main body, either directly or indirectly upon the inflatable bladder main body, without the inflatable bladder main body exterior wall rupture, the inflatable bladder main body capable of retaining the temperature-controlled fluid within the at least one inflatable bladder main body exterior wall, unless intentionally released to the substrate, casing layer, aerial mycelium layer or combination thereof which are supported by the inflatable bladder main body, the inflatable bladder main body capable of either imparting heat, or absorbing heat by the at least one inflatable bladder main body exterior wall to or from materials adjacent the inflatable bladder main body; a feeder conduit, for feeding temperature-controlled fluid to the inflatable bladder main body; a processor or controller for controlling the temperature and flow of temperature-controlled fluid to be fed into the inflatable bladder main body through the feeder conduit, a circulating pump or fan for introducing temperature-controlled fluid into the inflatable bladder main body through the feeder conduit.

[0030] In yet another alternative embodiment, the heat exchanger apparatus system includes multiple heat exchangers with multiple inflatable bladder main bodies. In still a further alternative embodiment, the heat exchanger apparatus system includes heat exchangers that are each capable of independent, fluid temperature control and flow. In still a further alternative embodiment of a heat exchanger apparatus system, multiple inflatable bladder main bodies are in fluid communication with fluid from a surrounding growth environment. In yet a further embodiment of a heat exchanger apparatus system, multiple heat exchangers with inflatable bladder main bodies are connected to one another in a series. In still a further alternative embodiment of a heat exchanger apparatus system, one or more heat exchangers are independently capable of heating or cooling adjacent material layers. In still a further alternative embodiment of a heat exchanger apparatus system, one or more heat exchangers are capable of dispersing one or more of air, water, and/or nutrients to a growing horticultural product. In yet another alternative embodiment, a heat exchanger apparatus system includes multiple heat exchangers positioned on a rack having multiple shelves, with at least one heat exchanger being positioned on each shelf of the rack. In yet another alternative embodiment, in a heat exchanger apparatus system the temperature-controlled fluid used to inflate an inflatable bladder main body is recirculated within the system. In still another alternative embodiment, in a heat exchanger apparatus system temperature-controlled fluid used to inflate the inflatable bladder is capable of either heating or cooling materials adjacent the inflatable bladder.

[0031] In another alternative embodiment, a method for influencing growth of a horticultural product, and in particular aerial mycelium in numerous locations within a growth environment, includes the steps of: providing a surrounding growth environment for the growth of a horticultural product, and in particular, aerial mycelium, including at least one carrier structure; placing at least a horticultural product-seeded substrate, and in particular, a fungal-inoculated substrate, beneath a heat exchanger apparatus upon the carrier structure, the heat exchanger apparatus comprising an inflatable bladder, the inflatable bladder having an inflatable bladder main body, the inflatable bladder main body having at least one inflatable bladder main body exterior wall defining an inflatable bladder main body interior space, which at least one inflatable bladder main body exterior wall is inflatable by a temperature-controlled fluid such that its outer dimensions expand upon inflation by the temperature-controlled fluid into the inflatable bladder main body interior space, and which inflatable bladder, upon expansion of the outer dimensions, is capable of supporting the weight of a growth layer positioned vertically above the inflatable bladder, such as either a substrate, a casing layer, an aerial mycelium layer or a combination thereof placed or grown respectively upon the inflatable bladder main body, either directly or indirectly upon the inflatable bladder main body, without the inflatable bladder exterior wall rupture, the inflatable bladder capable of retaining the temperature-controlled fluid within the interior space defined by the least one exterior wall, unless intentionally released to the substrate, casing layer, aerial mycelium layer or combination thereof which are supported by the inflatable bladder main body, the inflatable bladder main body capable of either imparting heat, or absorbing heat through the at least one main body exterior wall to or from materials adjacent the inflatable bladder main body, and the inflatable bladder main body also capable of housing growing mycelium hyphae in its interior space, which mycelium hyphae enters and exits the inflatable bladder main body through hyphal extensions through the openings in the inflatable bladder main body exterior wall; and a feeder conduit, for feeding temperature-controlled fluid to the inflatable bladder main body; imparting growth conditions to the growth environment thereby allowing the horticultural product, and in particular, fungal inoculum to grow into a horticultural product, and in particular, aerial mycelium; inflating the inflatable bladder with a temperature-controlled fluid to either provide heat or absorb heat from material adjacent the inflatable bladder main body; regulating the temperature-controlled fluid such that the temperature of the temperature-controlled fluid facilitates growth of a horticultural product, and in particular, aerial mycelium in the growth environment within the inflatable bladder main body interior space, and also above a growth layer positioned vertically above the inflatable bladder main body.

Brief Description of the Drawings

[0032] The features and advantages of the methods and compositions described herein will become more fully apparent from the following description and appended claims, taken in conjunction with the accompanying drawings. These drawings depict only several embodiments in accordance with the disclosure and are not to be considered limiting of their scope. In the drawings, similar reference numbers or symbols typically identify similar components, unless context dictates otherwise. In some instances, the drawings may not be drawn to scale. So as to facilitate a better understanding of some embodiments of the invention, certain drawings illustrate internal features in phantom lines, which drawings are highlighted as they are arise.

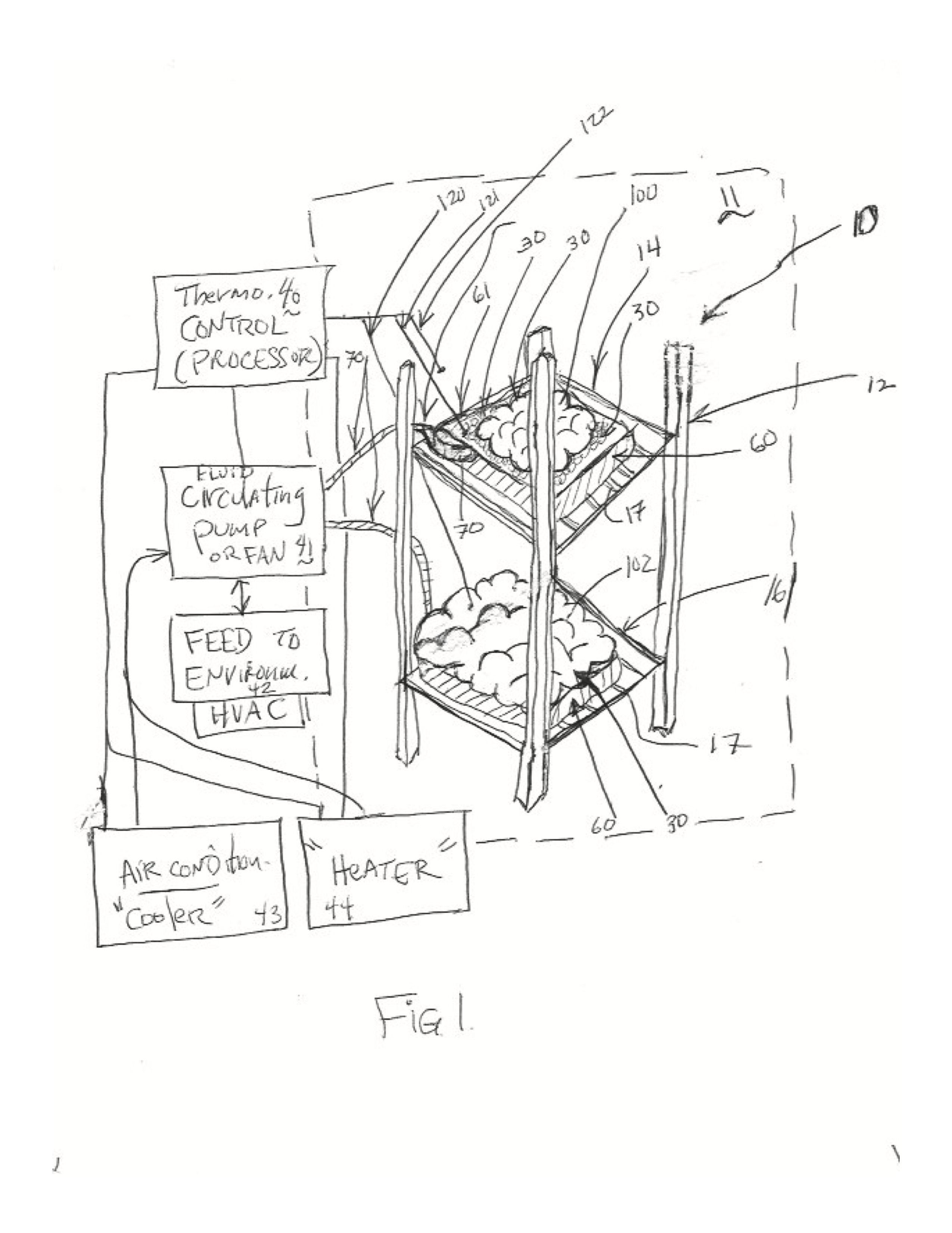

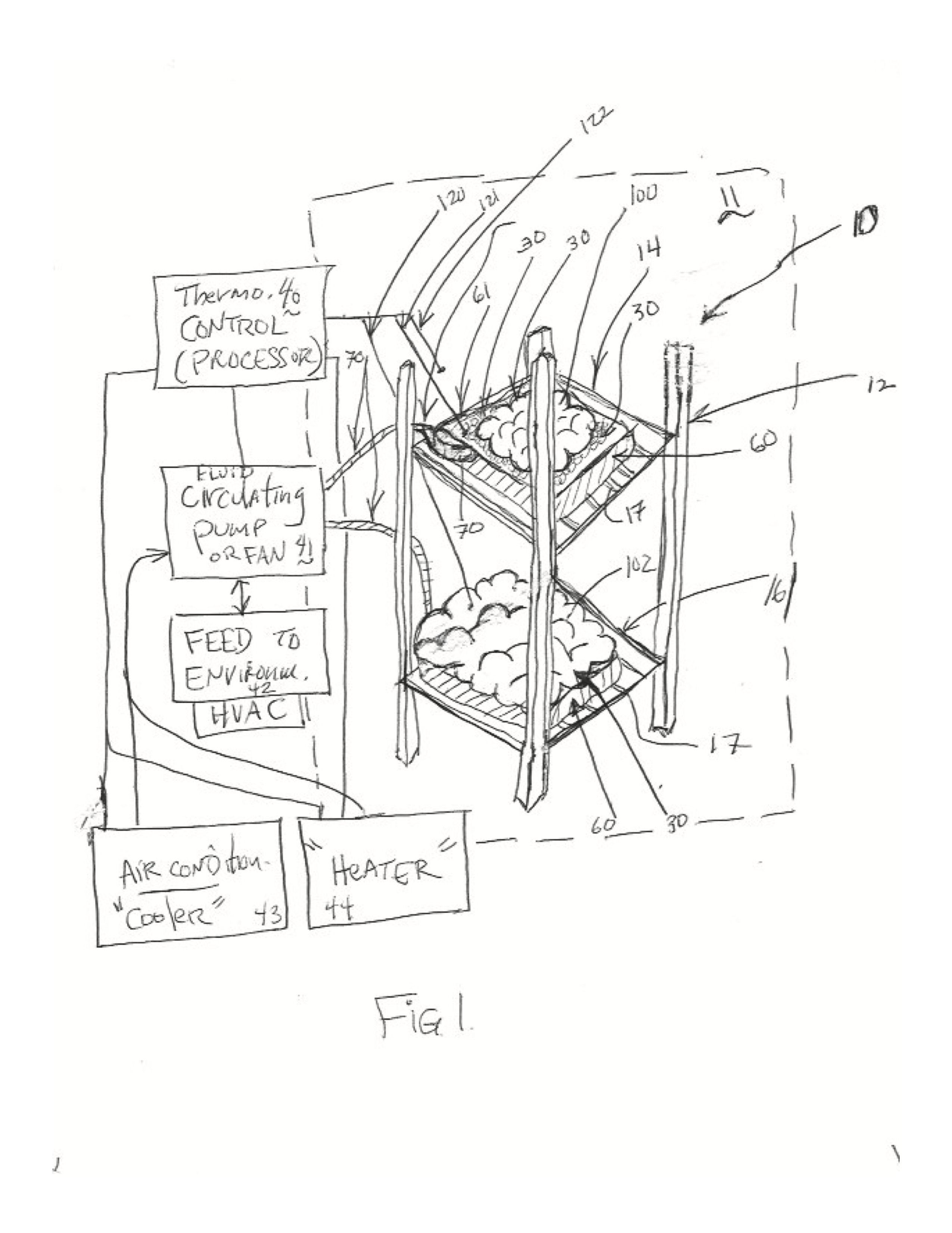

[0033] Fig. 1 illustrates a schematic/representational view of a heat exchanger system in accordance with the invention.

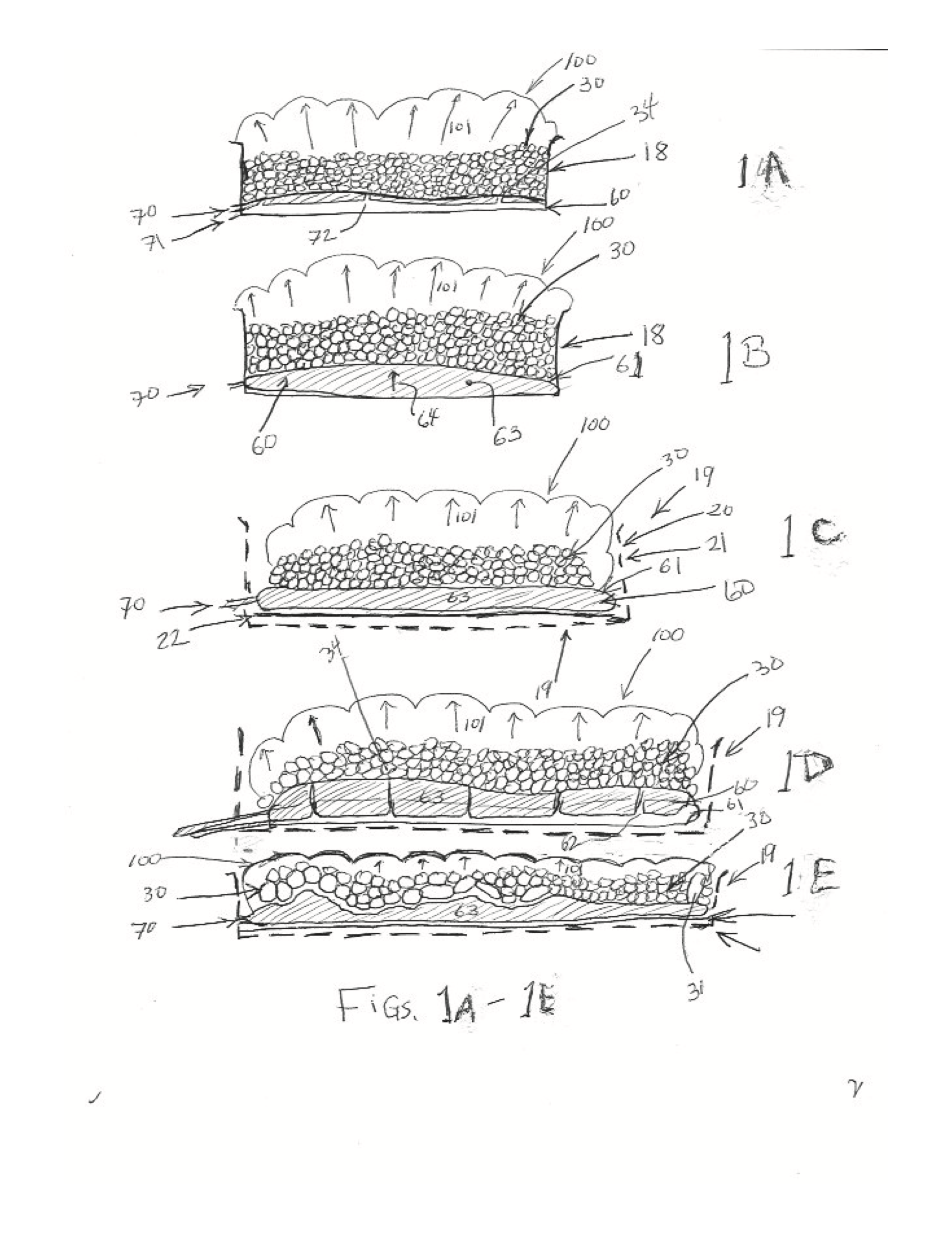

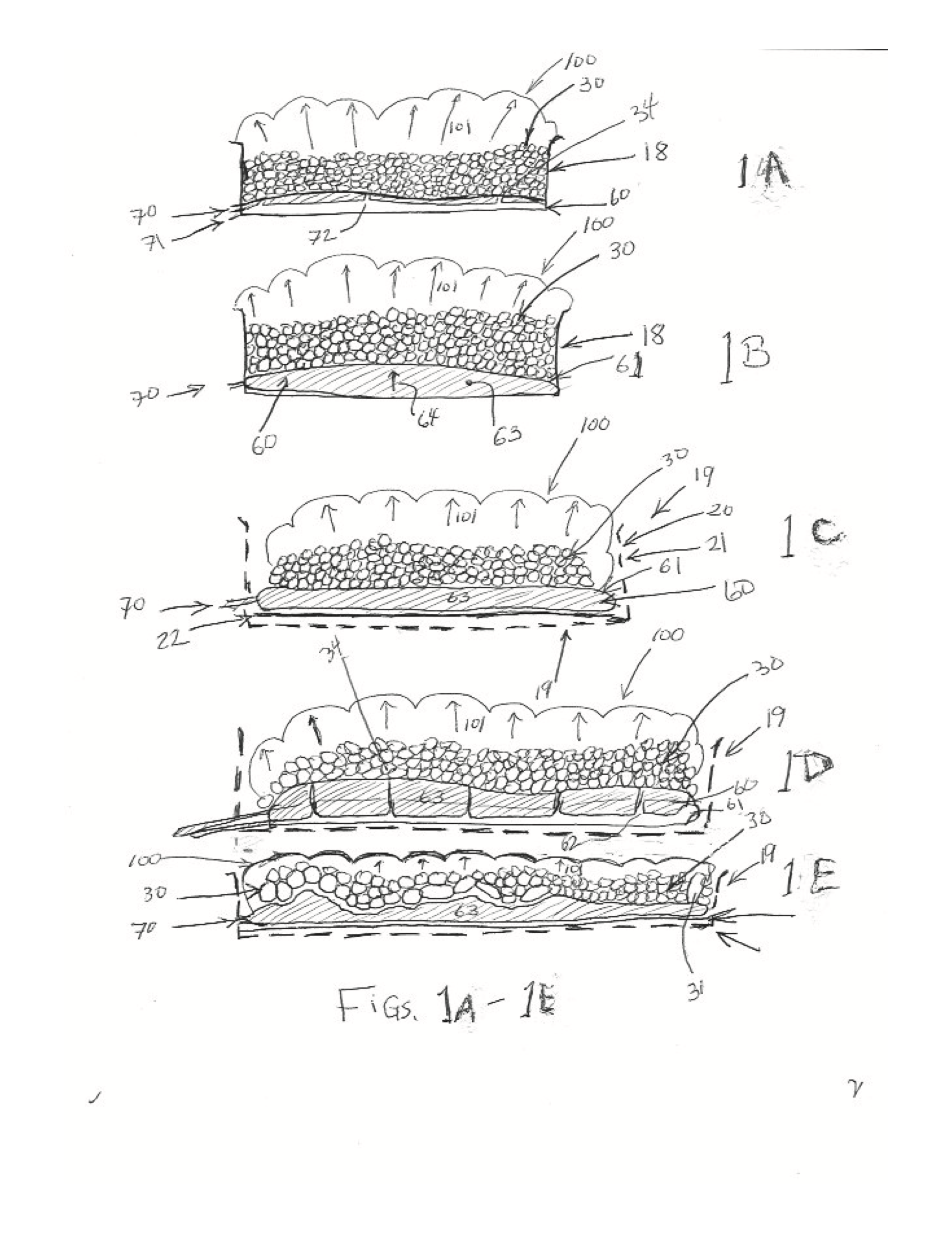

[0034] Fig. 1A illustrates a cross-sectional view of an embodiment of a heat exchanger in accordance with the invention.

[0035] Fig. 1B illustrates a further cross-sectional view of an alternative embodiment of a heat exchanger in accordance with the invention.

[0036] Fig. 1C illustrates still a further cross-sectional view of an alternative embodiment of a heat exchanger in accordance with the invention.

[0037] Fig. 1D illustrates still a further cross-sectional view of an alternative embodiment of a heat exchanger in accordance with the invention.

[0038] Fig. 1E illustrates still a further cross-sectional view of an alternative embodiment of a heat exchanger in accordance with the invention.

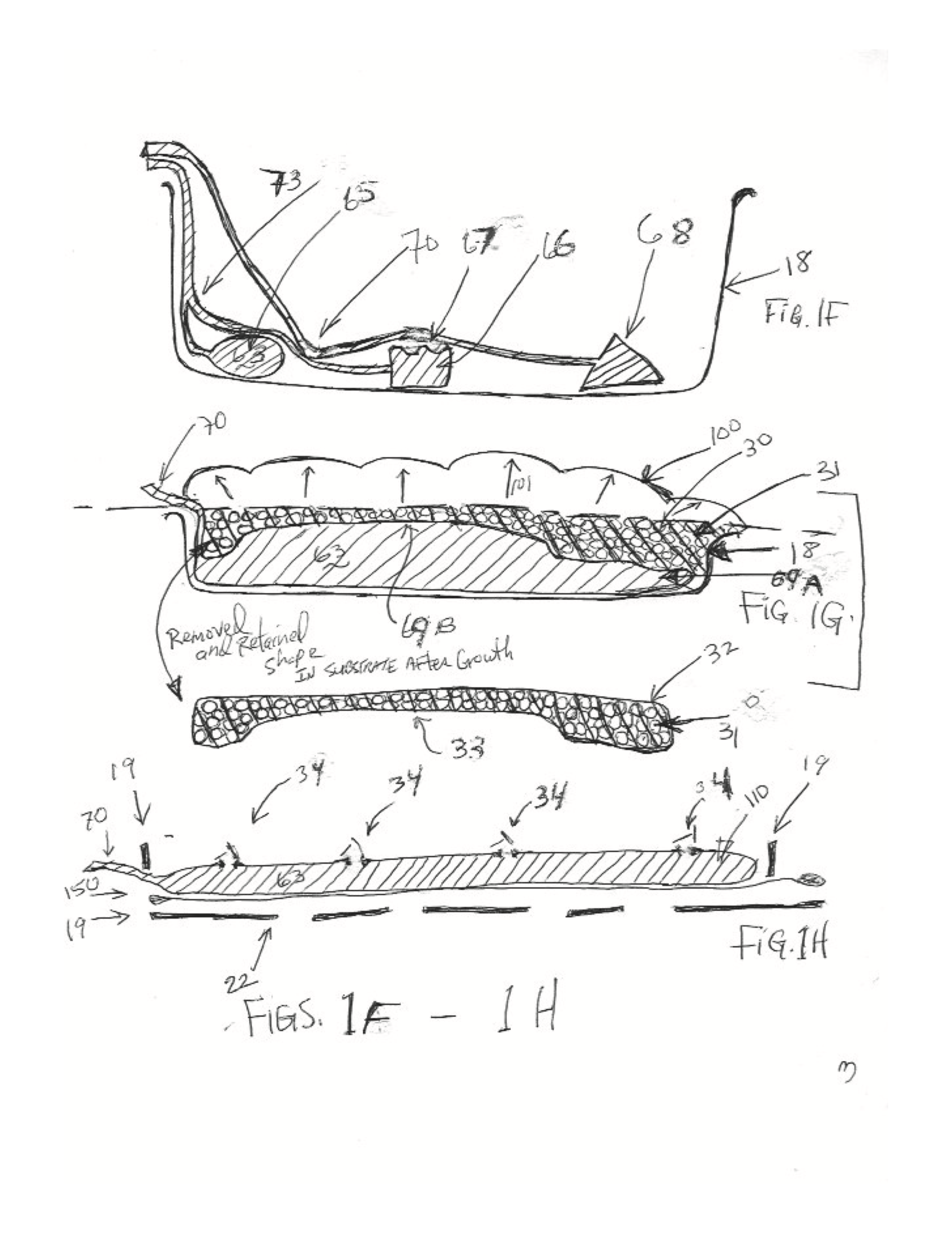

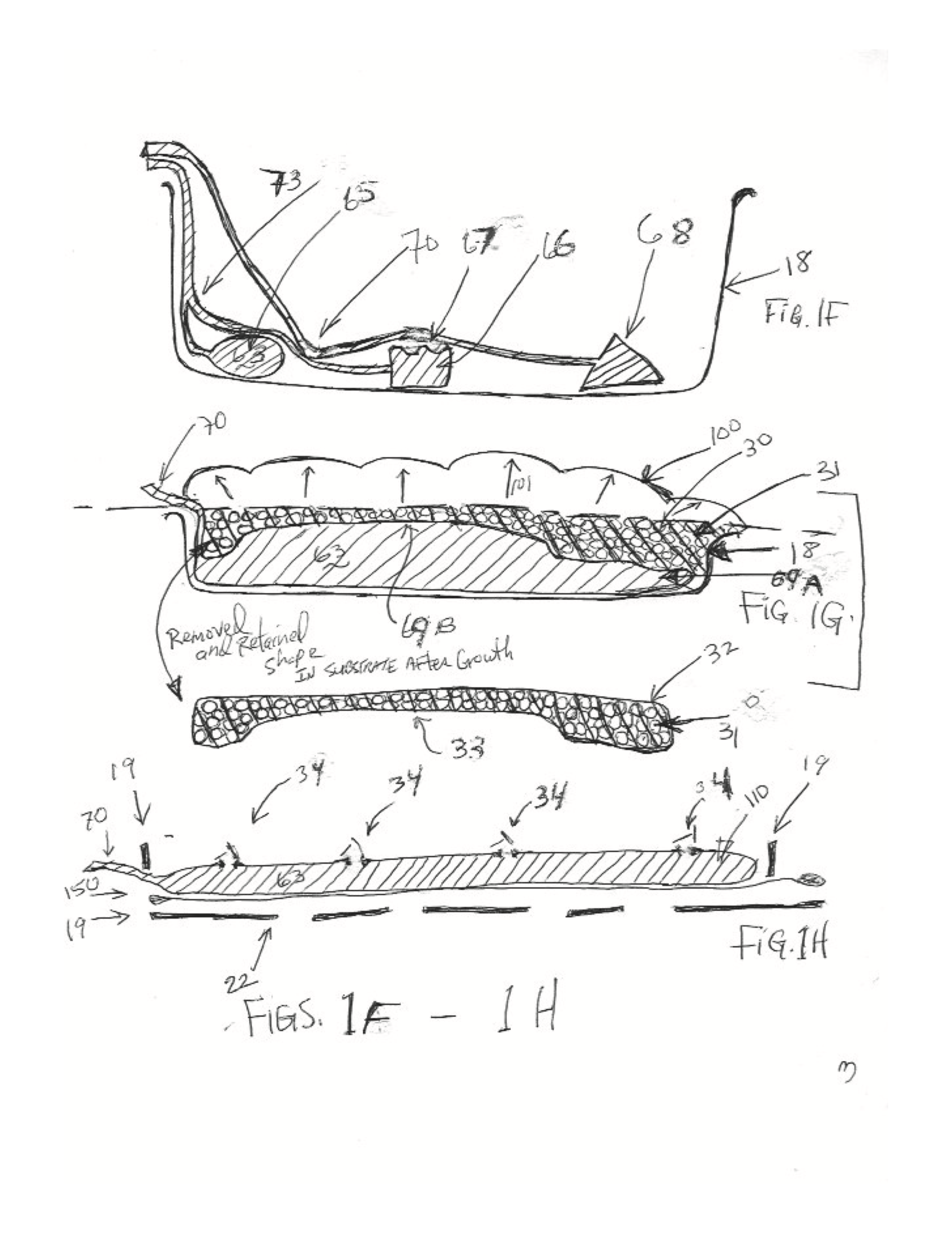

[0039] Fig. 1F illustrates still a further cross-sectional view of alternative embodiments of heat exchangers in accordance with the invention.

[0040] Fig. 1G illustrates still a further cross-sectional view of an alternative embodiment of a heat exchanger (and separately produced substrate) in accordance with the invention.

[0041] Fig. 1H illustrates still a further cross-sectional view of an alternative embodiment of a heat exchanger in accordance with the invention.

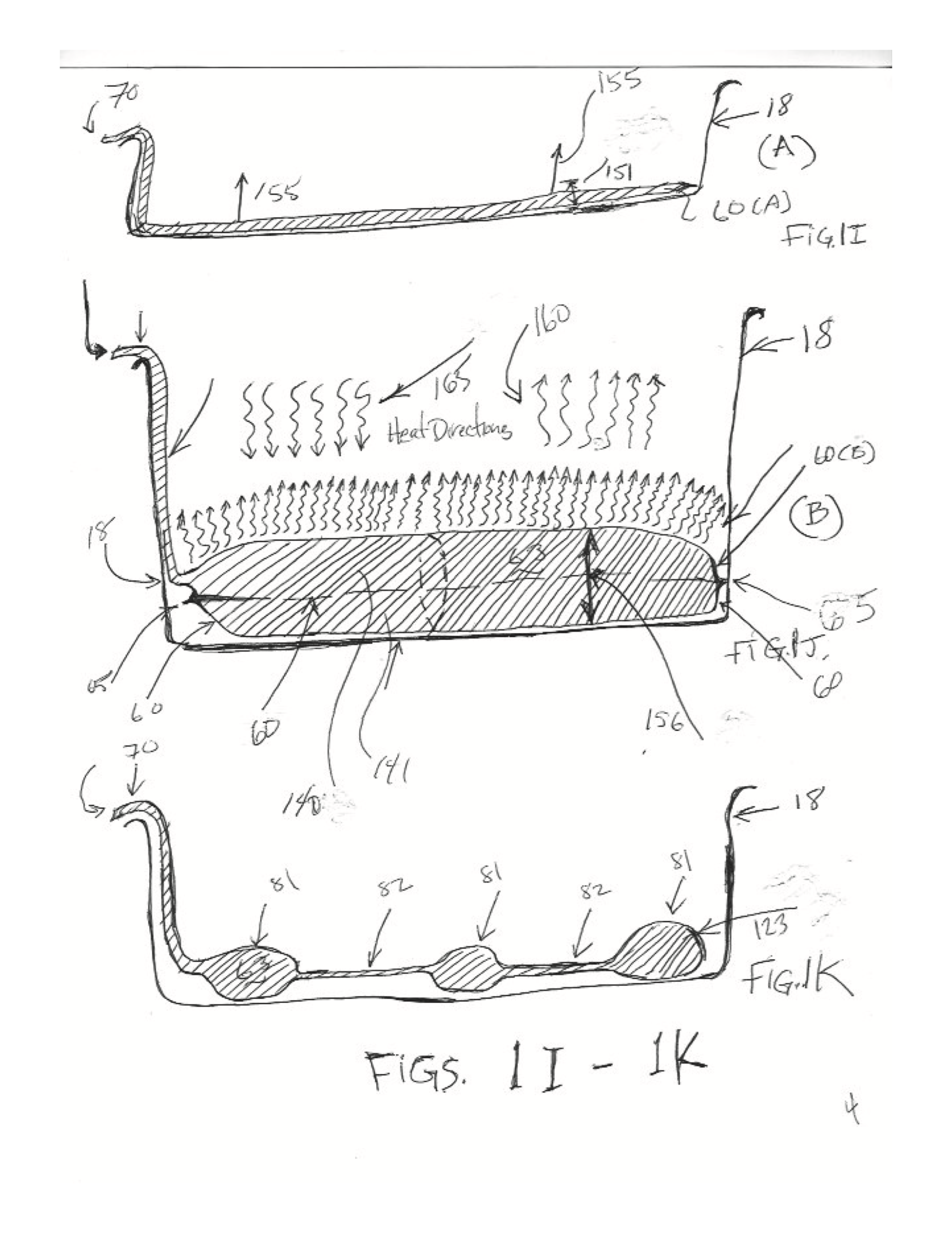

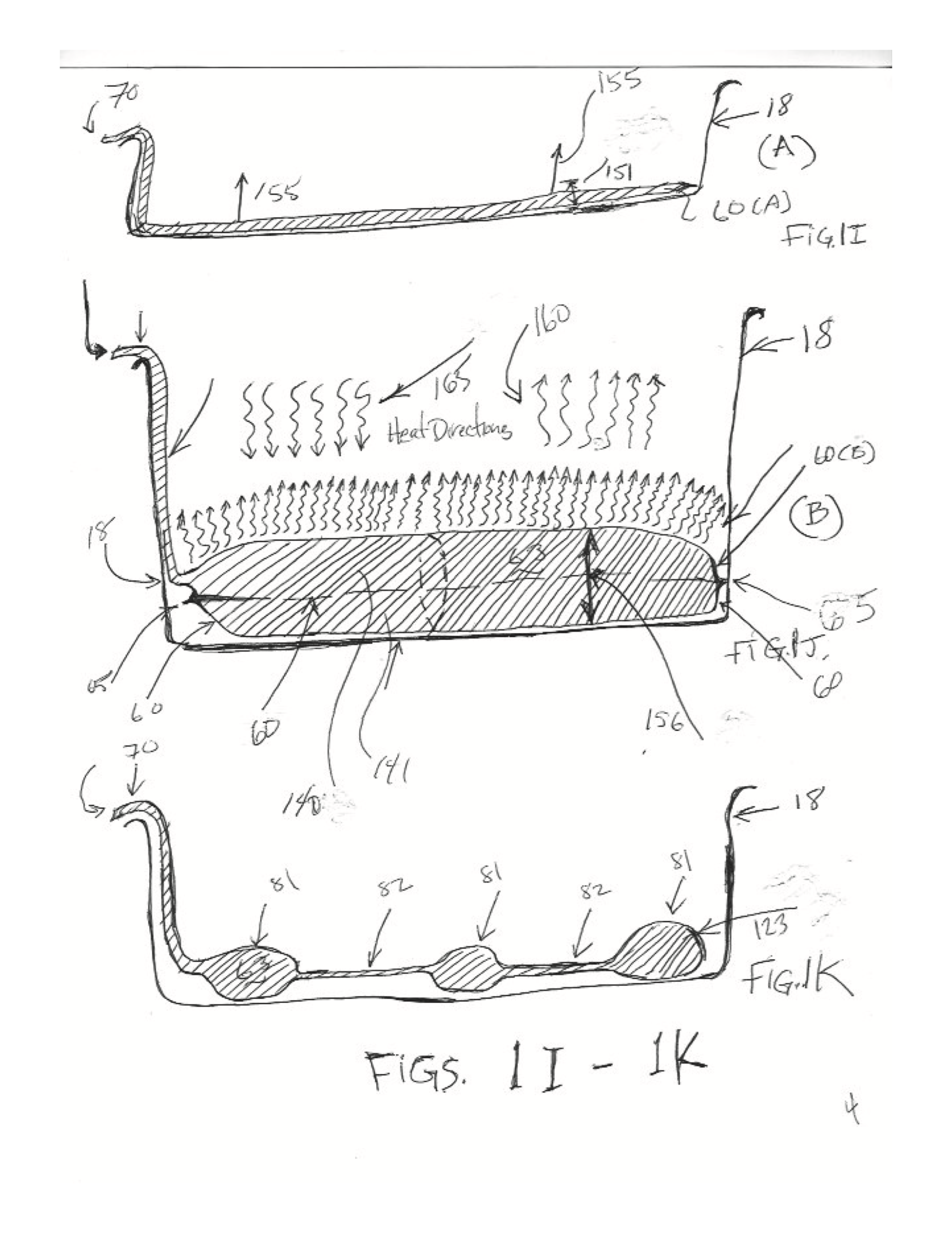

[0042] Fig. 1I (A) illustrates still a further cross-sectional view of an alternative embodiment of a heat exchanger (in a deflated state) in accordance with the invention.

[0043] Fig. 1J(B) illustrates the embodiment of Fig. 1I(A) after it has been expanded by fluid inflation.

[0044] Fig. 1K illustrates still a further alternative embodiment in cross-sectional view of a heat exchanger in accordance with the invention.

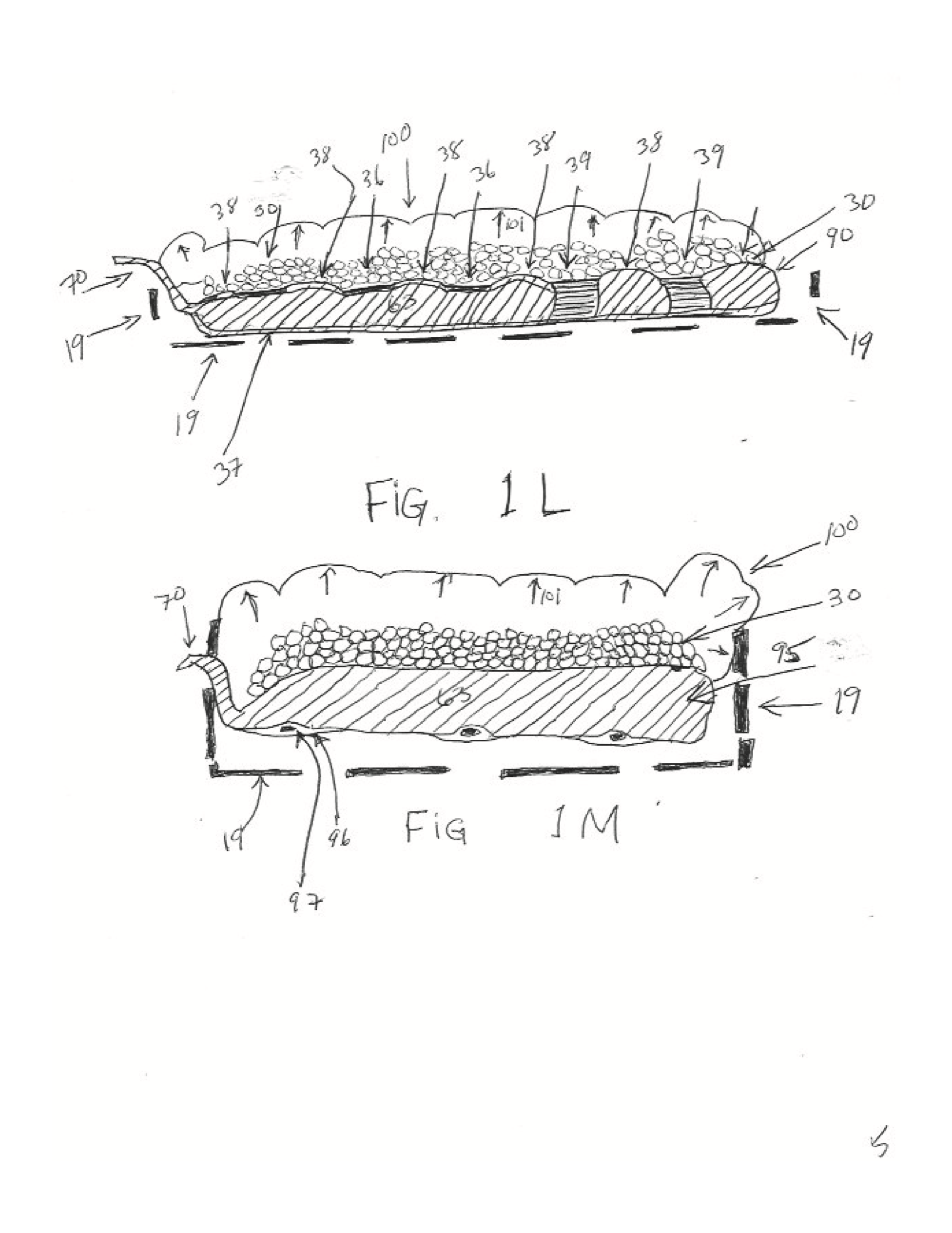

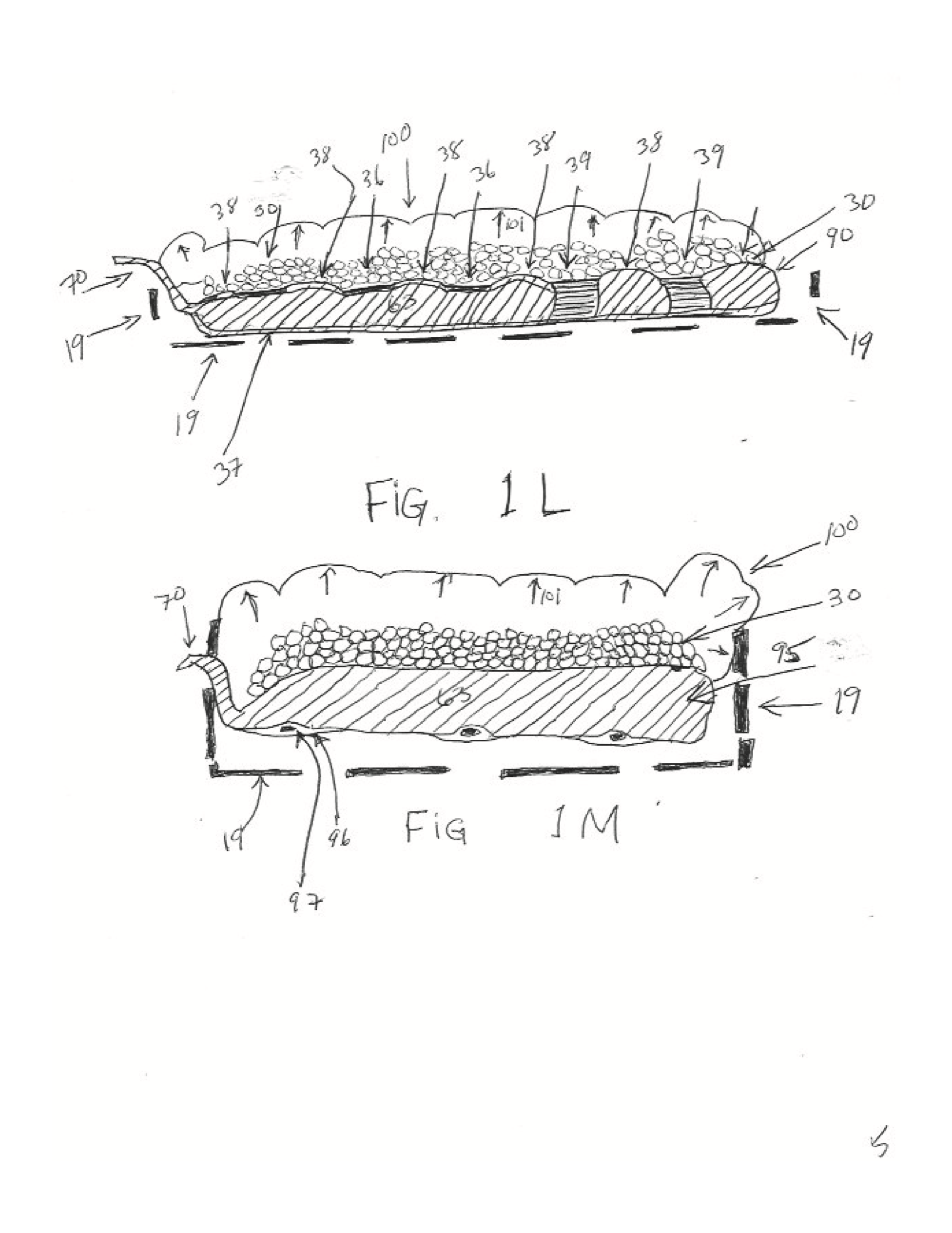

[0045] Fig. 1L illustrates still a further alternative embodiment in cross-sectional view of a heat exchanger surface and material features in accordance with the invention. It should be appreciated that while several of the features are shown present in one drawing, they may be present in various combinations in additional heat exchanger design configurations. For instance, each of the features may be present separately in separate heat exchanger design configurations.

[0046] Fig. 1M illustrates still a further alternative embodiment in cross-sectional view of a heat exchanger, and heat exchanger features in accordance with the invention.

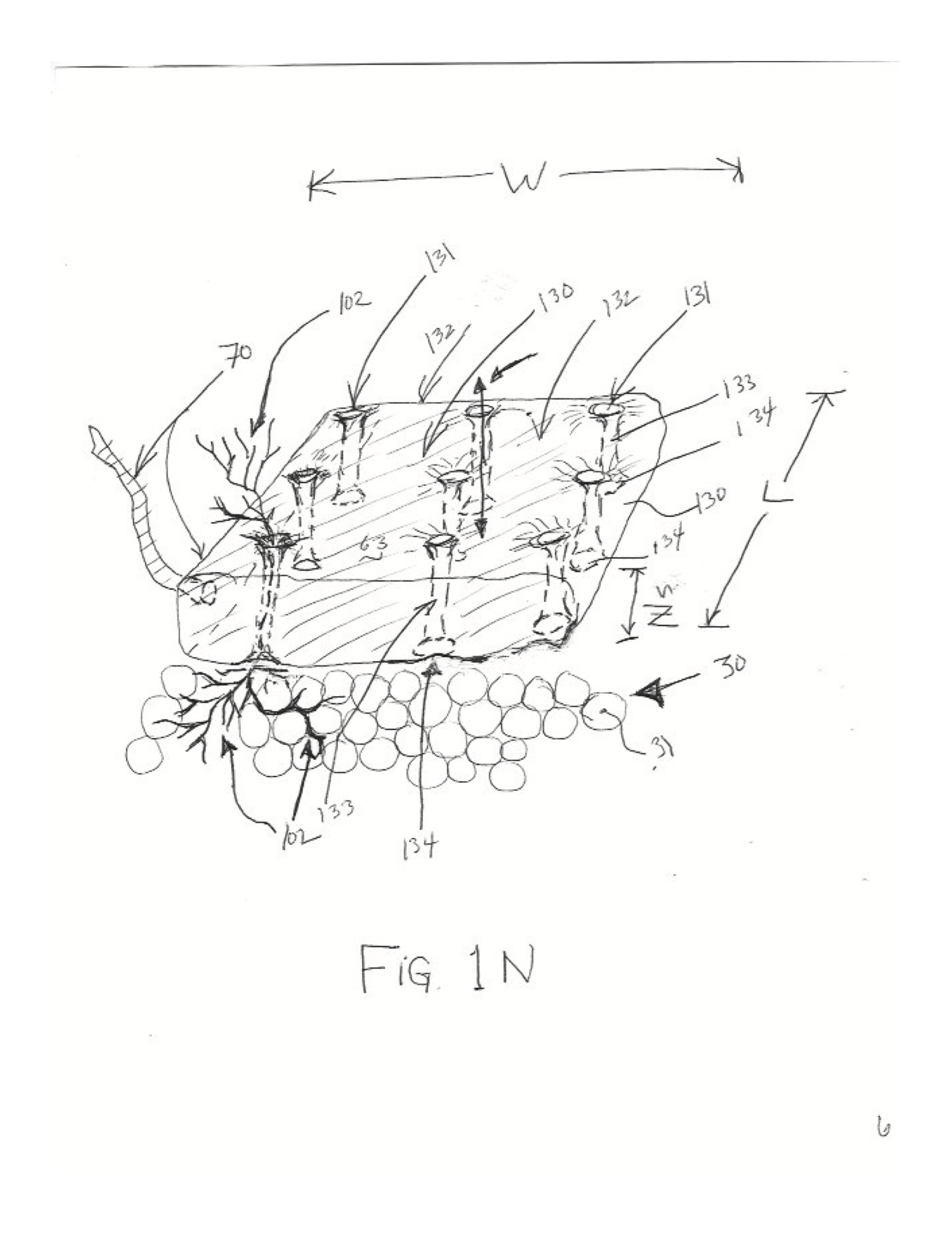

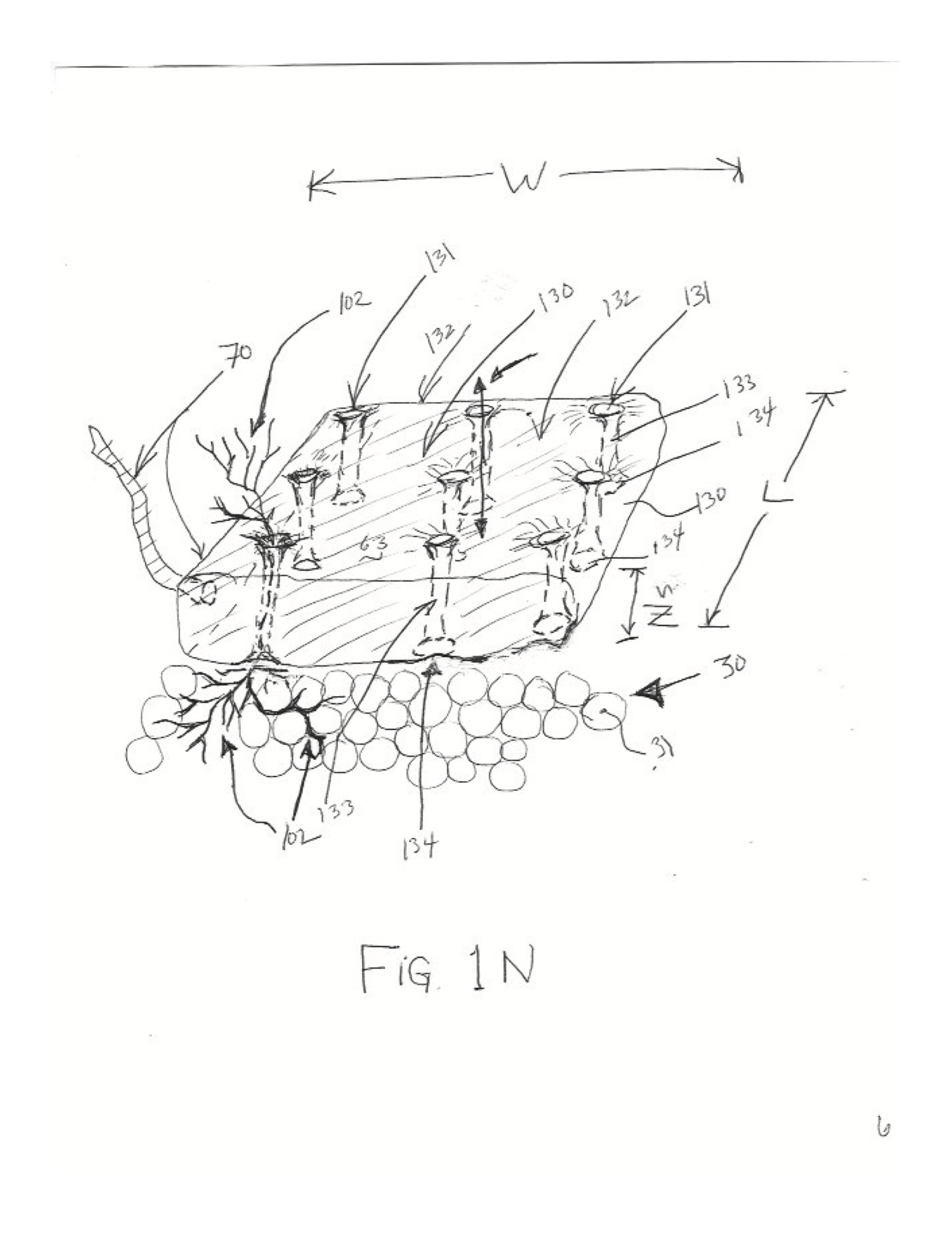

[0047] Fig. 1N illustrates still a further alternative embodiment in partial cross-sectional and perspective views of a heat exchanger in accordance with the invention, with internal heat exchanger features shown in phantom lines.

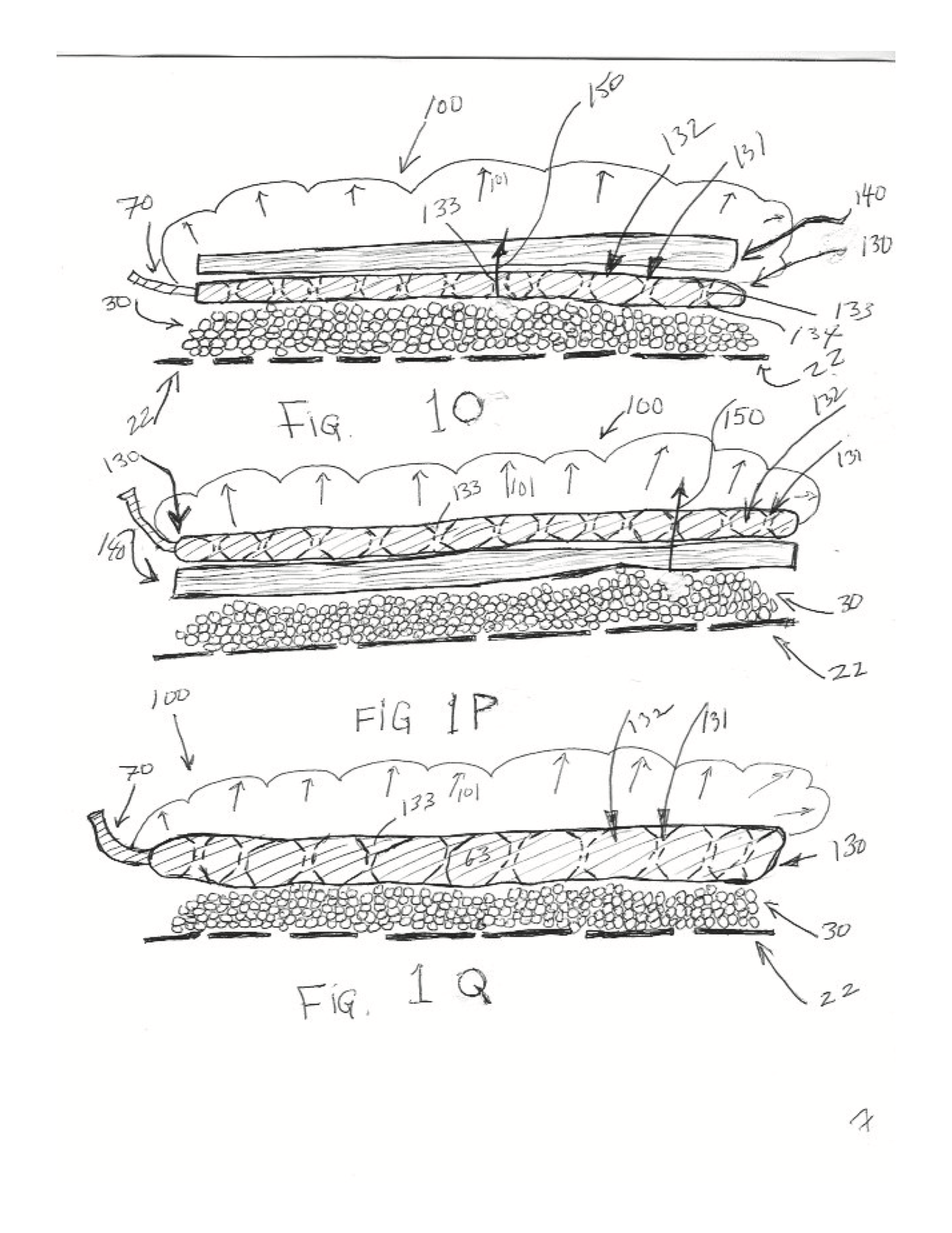

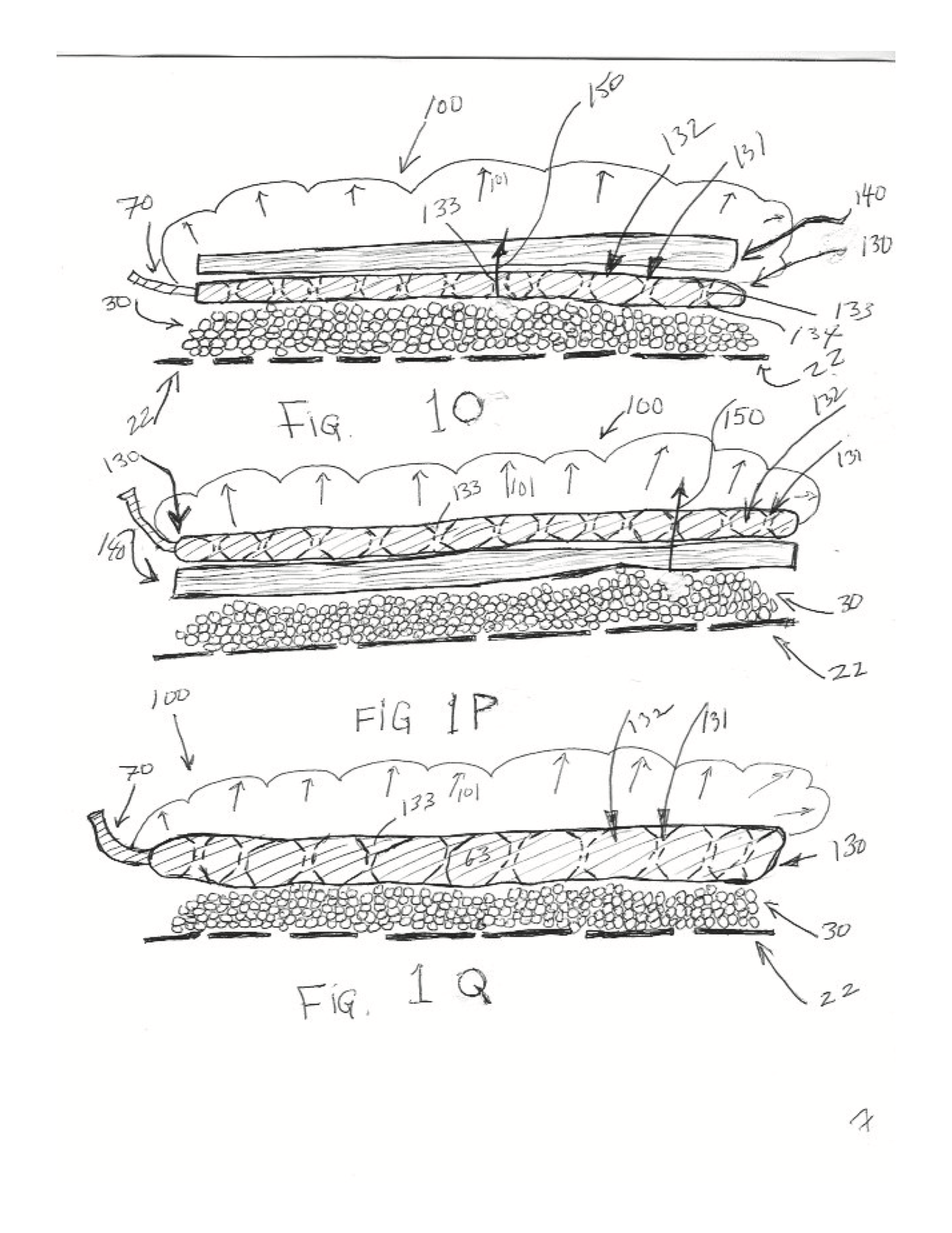

[0048] Fig. 1O illustrates the alternative embodiment of Fig. 1N in use, adjacent a lower substrate and upper casing layer.

[0049] Fig. 1P illustrates the alternative embodiment of Fig. 1N immediately adjacent a lower casing layer.

[0050] Fig. 1Q illustrates the alternative embodiment of Fig. 1N immediately adjacent a lower substrate layer.

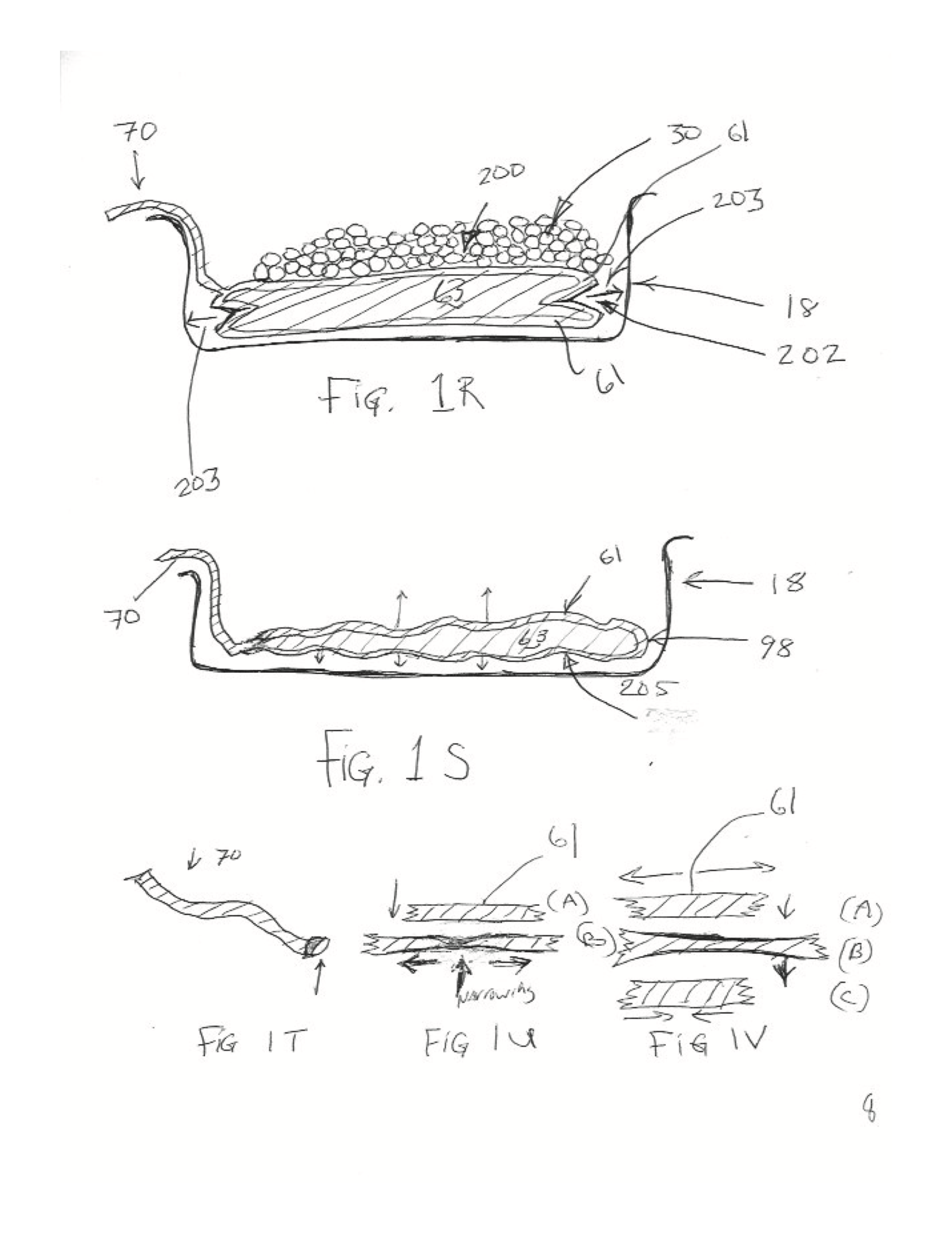

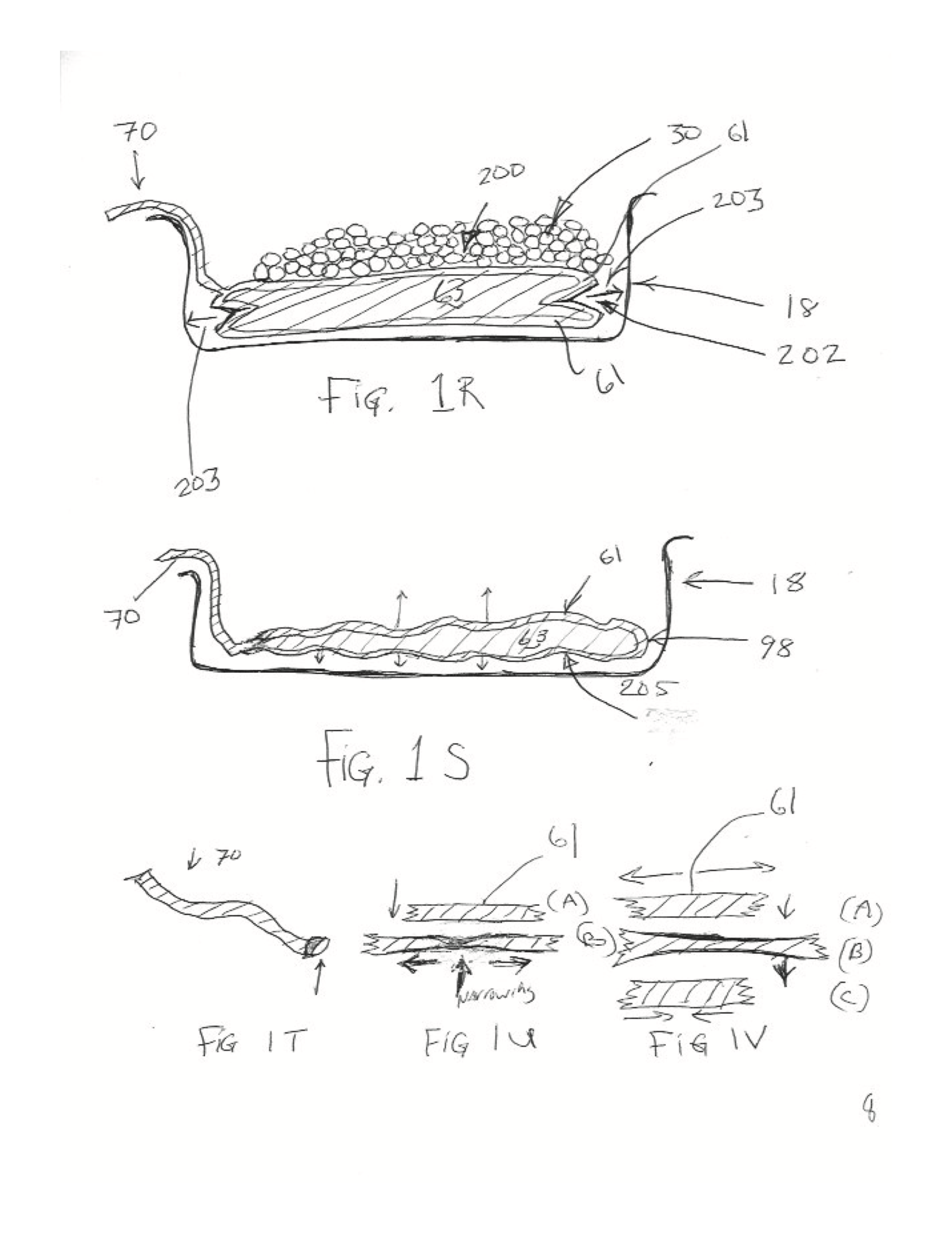

[0051] Fig. 1R illustrates an alternative embodiment in cross-sectional view of an inflatable bladder main body in accordance with one aspect of the invention, with folded, but expandable ends.

[0052] Fig. 1S illustrates an alternative embodiment in cross-sectional view of an inflatable bladder main body in accordance with one aspect of the invention, with gathered exterior walls for later expansion as a result of fluid inflation.

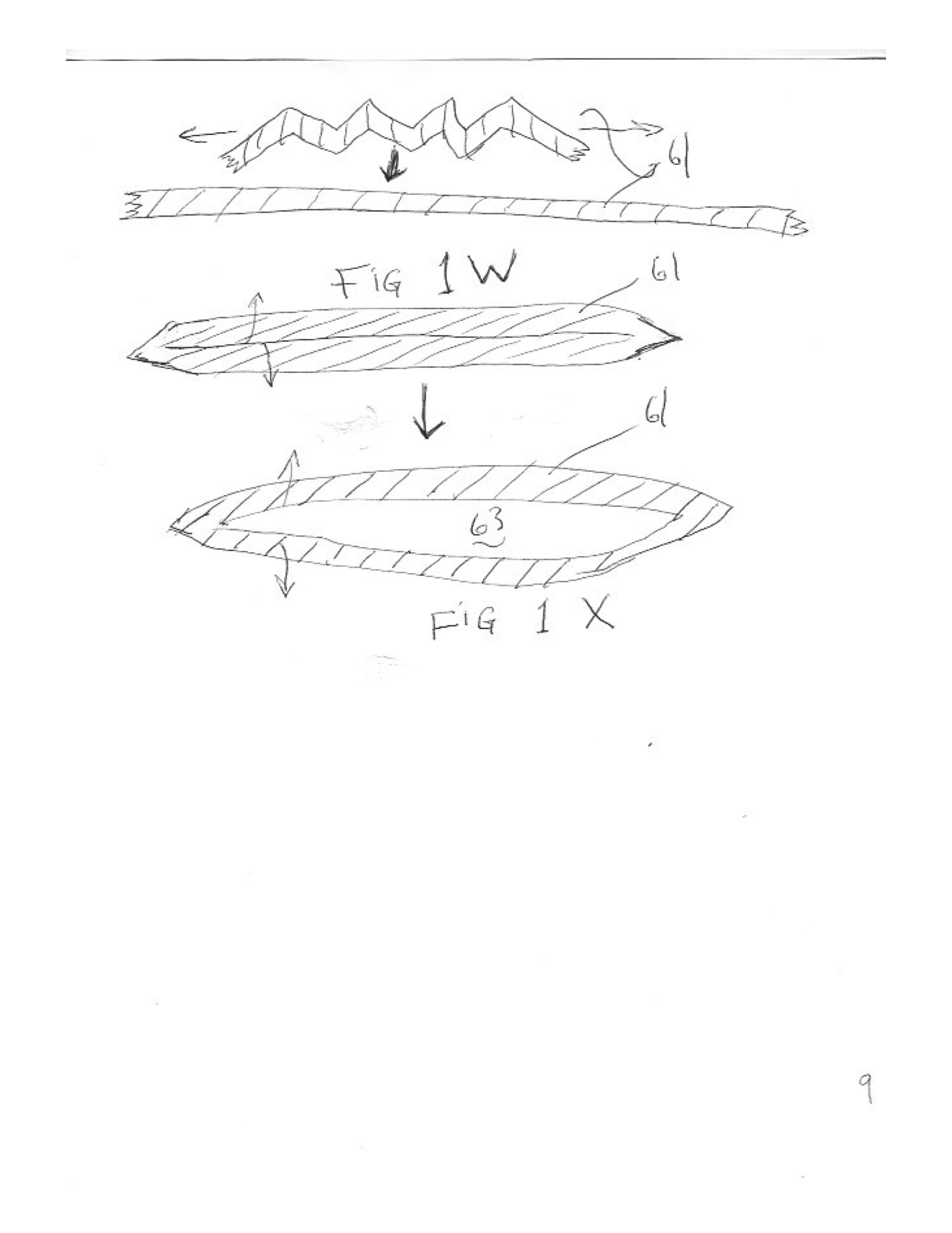

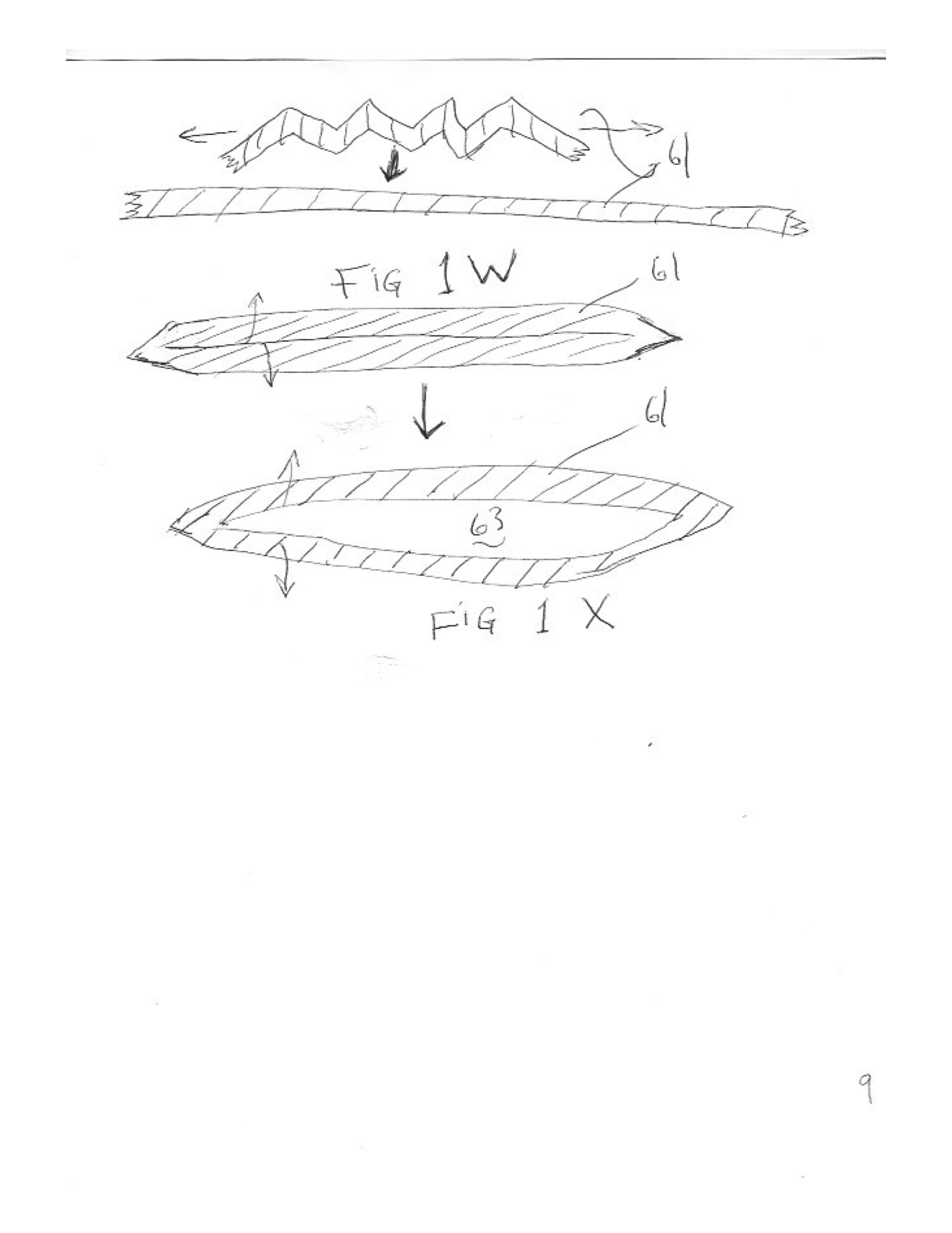

[0053] Figs. 1T-1X illustrate various aspects of the inflatable bladder and exterior wall in accordance with the invention, including the structure of the feeder conduit and embodiments relating to the expansive nature of the inflatable bladder exterior walls.

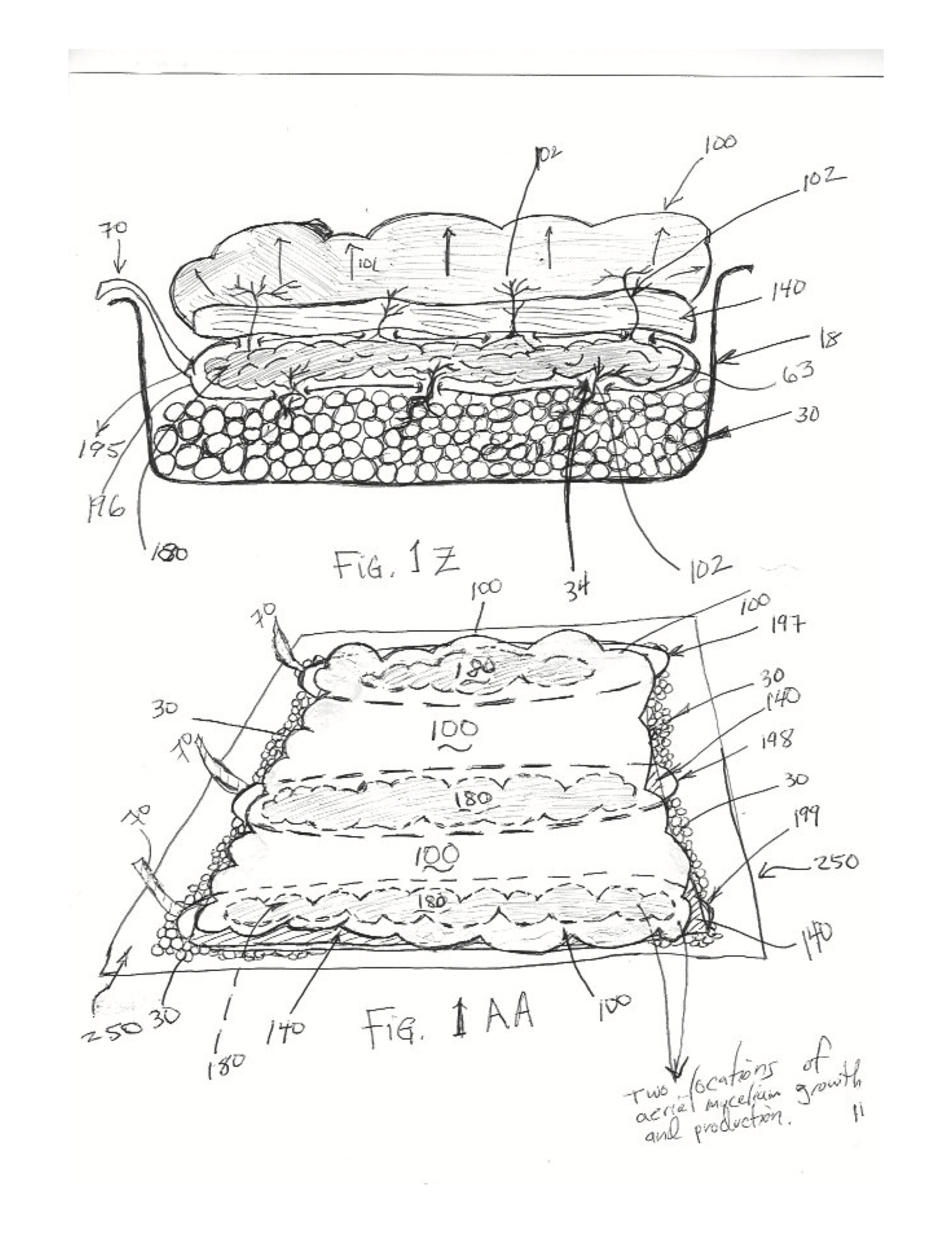

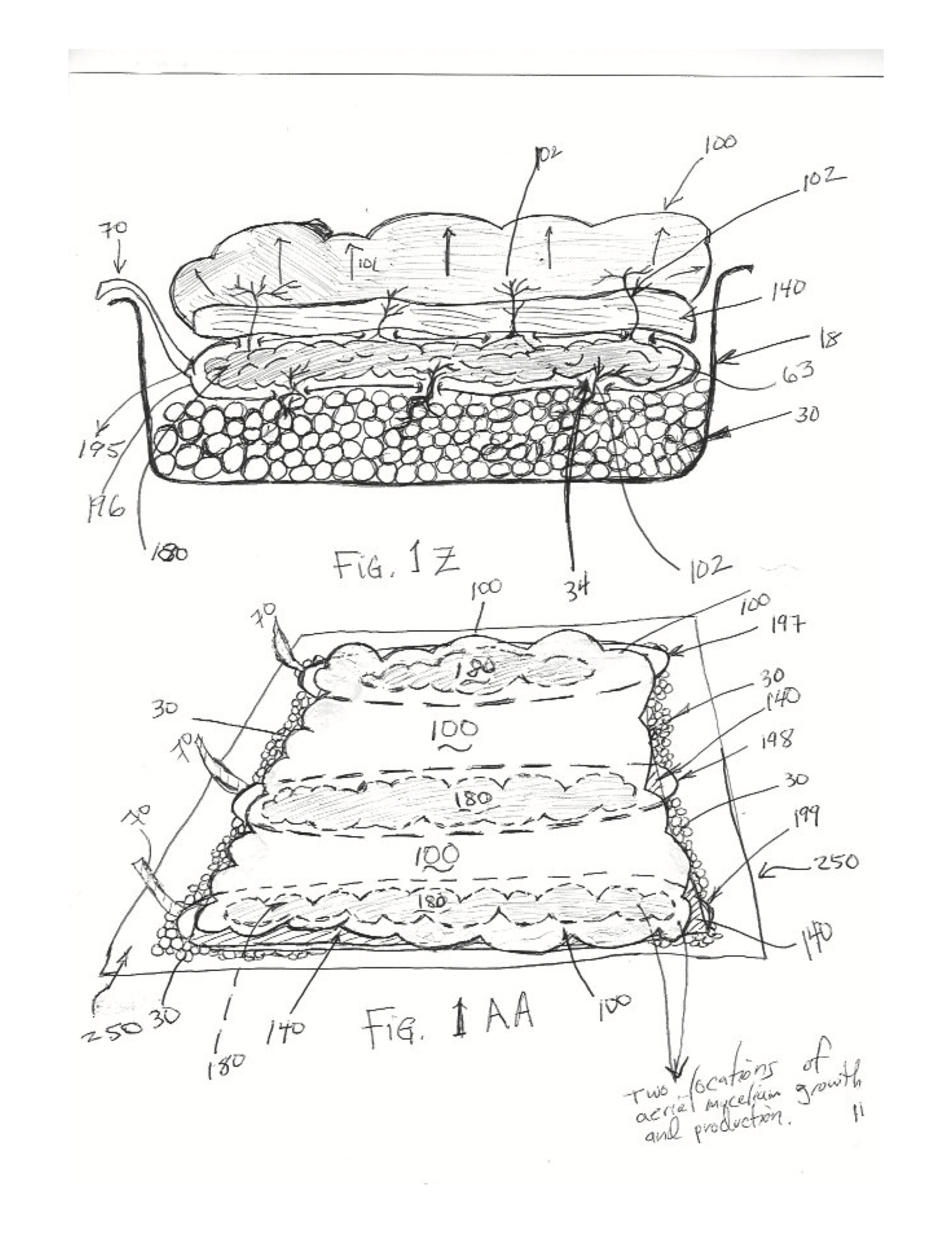

[0054] Fig. 1Z illustrates an alternative embodiment in cross-sectional view of an inflatable bladder main body having porous exterior walls, and closeable feeder conduit, which inflatable bladder is capable of holding and supporting the formation of aerial mycelium within its interior space between its exterior wall (s).

[0055] Fig. 1AA illustrates a partial perspective view (with interior structures shown in phantom lines) of a carrier structure in the form of a flat table or shelf, on which multiple inflatable barrier main bodies of multiple heat exchangers (as show in in Fig. 1Z) are situated upon a lower substrate layer, and beneath an upper casing layer, and in which the multiple inflatable barrier main bodies are capable of, and are shown holding aerial mycelium grown inside their bladder interior spaces, in addition to the grown aerial mycelium (extra-particle aerial mycelium) growing above the casing layer as described in earlier embodiments.

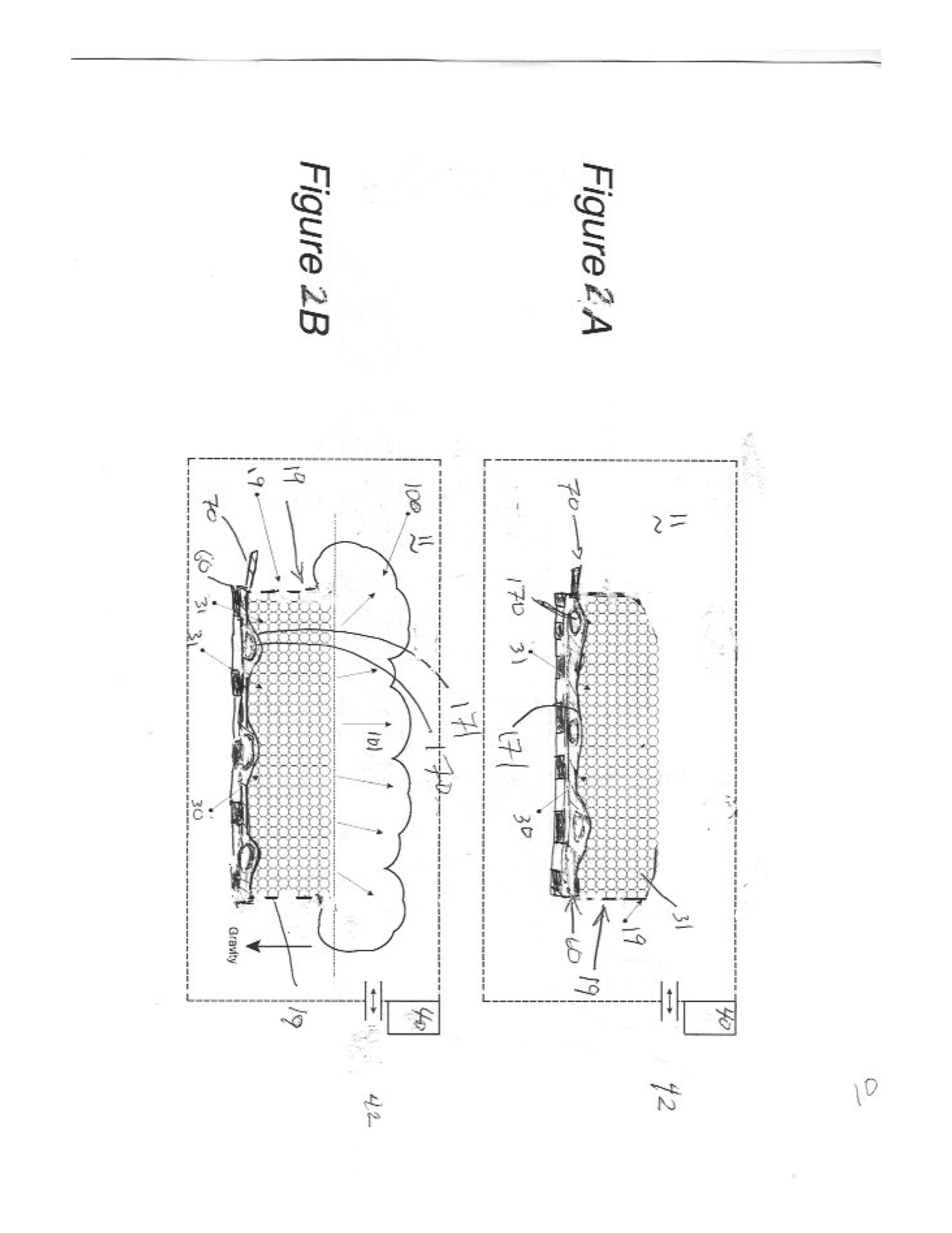

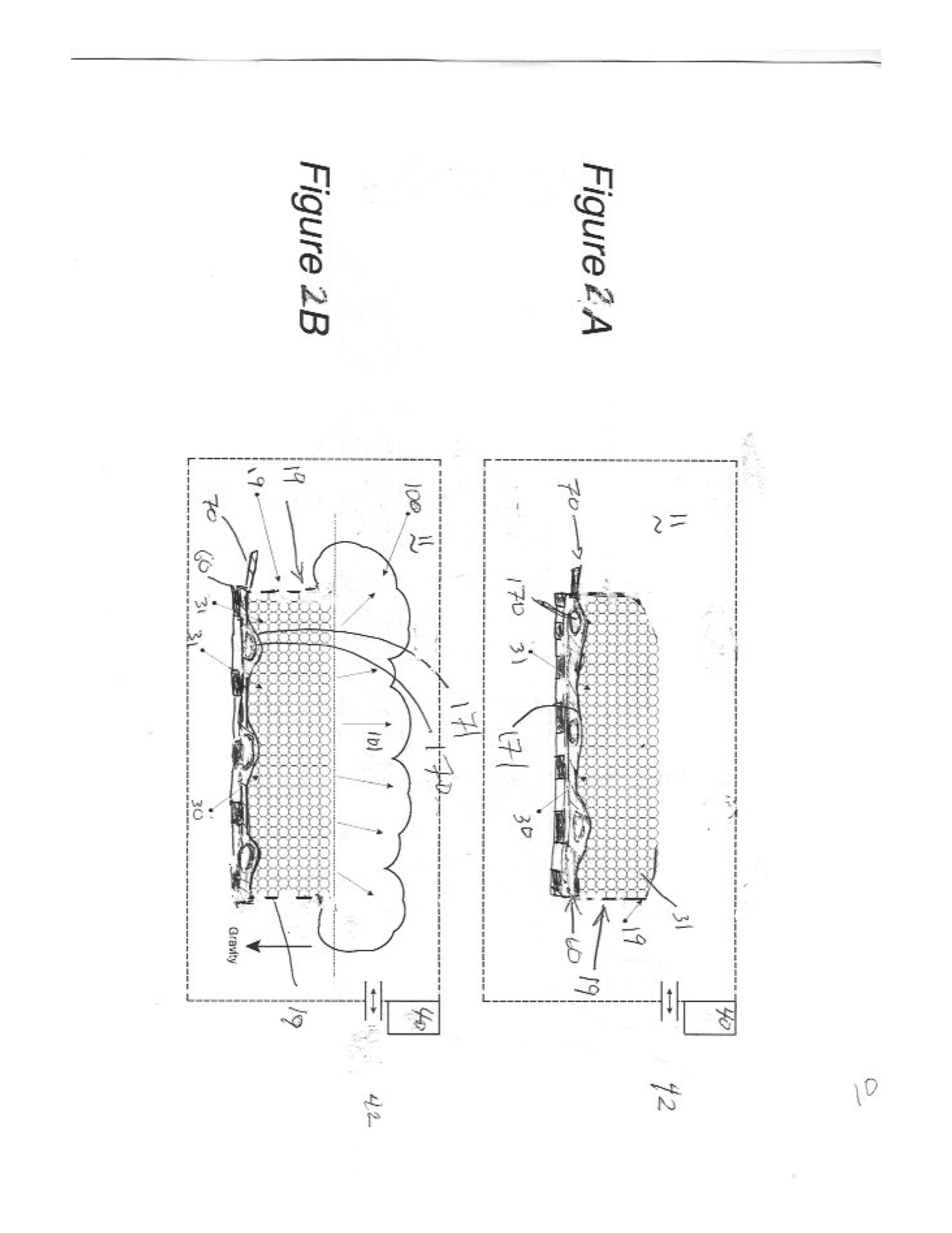

[0056] Fig. 2A illustrates an alternative embodiment in cross-sectional view of a heat exchanger in accordance with the invention.

[0057] Fig. 2B illustrates the heat exchanger of Fig. 2A during mycelial growth in accordance with the invention.

Detailed Description

[0058] The invention is described more fully hereinafter with reference to the accompanying description associated drawings, in which embodiments of the invention are shown. In the drawings, the absolute and relative sizes of systems, components, layers, and regions may be exaggerated for clarity. Embodiments may be described with reference to schematic, cross-sectional, partial cross-sectional, and perspective illustrations of various embodiments and intermediate structures of the invention. Embodiments may also be shown and described with interior features (normally not seen) but shown in phantom lines for the purpose of clarity. In the description and drawings, like numbers may refer to like elements throughout, except where the use of different numbers may instead assist in highlighting other differentiated features contained in particular embodiments. Relative terms as well as derivatives thereof should be construed to refer to the orientation as then described or as shown in the drawing under discussion. These relative terms are for convenience of description and do not require that the system be constructed or operated in a particular orientation unless stated otherwise.

Definitions

[0059] “Mycelium” as used herein refers to a connective network of fungal hyphae, with mycelia being the plural form of mycelium.

[0060] “Hyphae” or “hypha” as used herein refers to branched filament vegetative cellular structures that are interwoven to form mycelium.

[0061] “Fruiting body” as used herein refers to a fungal stipe, pileus, gill, pore structure, or a combination thereof, and may also be referred to herein as “mushroom.”

[0062] “Substrate” as used herein refers to a material or surface thereof, from or on which an organism lives, grows, and/or obtains its nourishment. In some embodiments, a substrate provides sufficient nutrition to the organism under target growth conditions such that the organism can live and grow without providing the organism a further source of nutrients. A variety of substrates are suitable to support the growth of an aerial mycelium of the present disclosure. Suitable substrates are disclosed, for example, in United States Publication 2020/0239830A1 to O’Brien et al., the contents of which are hereby incorporated by reference in their entirety to the extent not inconsistent with the content of this disclosure. In some embodiments, the substrate is a natural substrate. Non-limiting examples of a natural substrate include a lignocellulosic substrate, a cellulosic substrate, or a lignin-free substrate. A natural substrate can be an agricultural waste product or one that is purposefully harvested for the intended purpose of food production, including mycelial-based food production. Further non-limiting examples of substrates suitable for supporting the growth of mycelia of the present disclosure include soy-based materials, oak-based materials, maple-based materials, corn-based materials, seed-based materials and the like, or combinations thereof. The materials can have a variety of particle sizes, as disclosed in US20200239830A1, and occur in a variety of forms, including shavings, pellets, chips, flakes, or flour, or can be in monolithic form. Non-limiting examples of suitable substrates for the production of mycelia (and aerial mycelia) of the present disclosure include corn stover, maple flour, maple flake, maple chips, soy flour, chickpea flour, millet seed flour, oak pellets, soybean hull pellets and combinations thereof. Additional useful substrates for the growth of mycelia are disclosed herein. A substrate can also be a depleted substrate, which is at least partially depleted of nutrients or other materials after extra-particle aerial mycelial growth has been grown and divided from the growth matrix (as in aerial mycelium) to form the separated aerial mycelium. A substrate or a depleted substrate can be substrate which has been further processed (e.g., chemically or mechanically) to improve its viability to support new mycelial growth (e.g., extra-particle aerial mycelial growth).

[0063] “Growth media” or “growth medium” as used herein refers to a matrix containing a substrate and an optional further source of nutrition that is the same or different than the substrate, wherein the substrate, the nutrition source, or both are intended for fungal consumption to support mycelial growth.

[0064] “Growth matrix” as used herein refers to a matrix containing a growth medium and a fungus. In some embodiments, the fungus is provided as a fungal inoculum; thus, in such embodiments, the growth matrix comprises a fungal-inoculated growth medium. In other embodiments, the growth matrix comprises a colonized substrate.

[0065] “Inoculated substrate” as used herein refers to a substrate that has been inoculated with fungal inoculum. For example, an inoculated substrate can be formed by combining an uninoculated substrate with a fungal inoculum. Alternatively, an inoculum can be a solid or liquid composition of any living organism or part thereof, including, but not limited to, bacteria, archaea, viruses, protozoa, algae, animal cells or tissue, plant cells or tissue, or any other living material. An inoculated substrate can be formed by combining an uninoculated substrate with a previously inoculated substrate. An inoculated substrate can be formed by combining an inoculated substrate with a colonized substrate.

[0066] “Colonized substrate” as used herein refers to an inoculated substrate that has been incubated for sufficient time to allow for fungal colonization. A colonized substrate of the present disclosure can be characterized as a contiguous hyphal mass grown throughout the entirety of the volume of the growth media substrate. The colonized substrate may further contain residual nutrition that has not been consumed by the colonizing fungus. As is understood by persons of ordinary skill in the art, a colonized substrate has undergone primary myceliation, sometimes referred to by skilled artisans as having undergone a “mycelium run.” Thus, in some particular aspects, a colonized substrate consists essentially of a substrate and a colonizing fungus in a primary myceliation phase. For many fungal species, asexual sporulation occurs as part of normal vegetative growth, and as such could occur during the colonization process. Accordingly, in some embodiments, a colonized substrate of the present disclosure may also contain asexual spores (conidia). In some aspects, a colonized substrate of the present disclosure can exclude growth progression into sexual reproduction and/or vegetative foraging. Sexual reproduction includes fruiting body formation (e.g., primordiation and differentiation) and sexual sporulation (meiotic sporulation). Vegetative foraging includes any mycelial growth away from the colonizing substrate (such as aerial growth). Thus, in some further aspects, a colonized substrate can exclude mycelium that is in a vertical expansion phase of growth. A colonized substrate can enter a mycelial vertical expansion phase during incubation in a growth environment of the present disclosure. For example, a colonized substrate can enter a mycelial vertical expansion phase upon introducing aqueous mist into the growth environment and/or depositing aqueous mist onto colonized substrate and/or any ensuing extra-particle growth. In some embodiments, the use of aqueous mist can be adjusted, for example, to desired levels, direction, composition, and timing, to affect the topology, morphology, density, and/or volume of the growth. In some further embodiments, mist can be comprised of two or more liquid compositions. For example, introduction of liquid mist can be sourced from reservoirs of liquid water, liquid nutrients, liquid dye, liquid flavoring, liquid texturizing solutions, liquid tenderizing solutions, liquid mineral solutions, or any other liquid solution that can affect the topology, geometry and/or morphology of aerial mycelium.

[0067] Any suitable substrate can be used alone, or optionally combined with a nutrient source, as media to support mycelial growth. The growth media can be hydrated to a final target moisture content prior to inoculation with a fungal inoculum. In a non-limiting example, the substrate or growth media can be hydrated to a final moisture content of at least about 50% (w/w), at most about 95% w/w, within a range of about 50% to about 95%. Growth media hydration can be achieved via the addition of any suitable source of moisture. In a non-limiting example, the moisture source can be airborne or non-airborne liquid phase water (or other liquids), an aqueous solution containing one or more additives (including but not limited to a nutrient source), and/or gas phase water (or other compound). In some embodiments, at least a portion of the moisture is derived from steam utilized during bioburden reduction of the growth media. In some embodiments, inoculation of the growth media with the fungal inoculum can include a further hydration step to achieve a target moisture content, which can be the same or different than the moisture content of the growth media. For example, if growth media loses moisture during fungal inoculation, the fungal inoculated growth media can be hydrated to compensate for the lost moisture.

[0068] Methods for the growth and production of aerial mycelium disclosed herein can include an inoculation stage, wherein an inoculum is used to transport an organism into a substrate. The inoculum, which carries a desired fungal strain, is produced in sufficient quantities to inoculate a target quantity of substrate. The inoculation can provide a plurality of myceliation sites (nucleation points) distributed throughout the substrate. Inoculum can take the form of a liquid, a slurry, or a solid, or any other known vehicle for transporting an organism from one growth-supporting environment to another. Generally, the inoculum comprises water, carbohydrates, sugars, vitamins, other nutrients, and at least one fungus. The inoculum may contain enzymatically available carbon and nitrogen sources (e.g., lignocellulosic biomass, chitinous biomass, carbohydrates) augmented with additional micronutrients (e.g., vitamins, minerals). The inoculum can contain inert materials (e.g., perlite). In a non-limiting example, the fungal inoculum can be a seed-supported fungal inoculum, a feed-grain-supported fungal inoculum, a seed-sawdust mixture fungal inoculum, or another commercially available fungal inoculum, including specialty proprietary spawn types provided by inoculum retailers. In some aspects, a fungal inoculum can be characterized by its density. In some embodiments, a fungal inoculum has a density of about 0.1 gram per cubic inch to about 10 grams per cubic inch, or from about 1 gram per cubic inch to about 7 grams per cubic inch. A skilled person can modify variables including the substrate or growth media component identities, substrate or growth media nutrition profile, substrate or growth media moisture content, substrate or growth media bioburden, inoculation rate, and inoculum constituent concentrations to arrive at a suitable medium to support aerial mycelial growth.

[0069] “Growth environment” as used herein refers to an environment that supports the growth of mycelia, as would be readily understood by a person of ordinary skill in the art in the mycelial cultivation industry, which contains a growth atmosphere having a gaseous environment of carbon dioxide (CO2), oxygen (O2), and a balance of other atmospheric gases including nitrogen (N2), and which is further characterized as having a relative humidity. In some aspects of the present disclosure, the growth atmosphere can have a CO2 content of at least about 0.02% (v/v), at least about 0.6%, at least about 5% (v/v), less than about 10% (v/v), less than about 8% (v/v), less than about 7%, between about 0.02% and 10%, between about 0.02% and 8%, between about 0.6% and about 7%, between about 5% and about 10%, or between about 5% and about 8%. In some other aspects, the growth atmosphere can have an O2 content of at least about 12% (v/v), or at least about 14% (v/v), and at most about 21% (v/v). In yet other aspects, the growth atmosphere can have an N2 content of at most about 79% (v/v). Each foregoing CO2, O2 or N2 content is based on a dry gaseous environment, notwithstanding the growth environment atmosphere relative humidity. “A portion of the growth environment” as used herein refers to a percentage of the total volume of the growth environment. For example, a portion of the growth environment can encompass between 0.01% to 100% of the total volume of the growth environment. A portion of the growth environment can refer to any fraction of the one-dimensional, two-dimensional or three-dimensional geometry comprising the growth environment. For example, a portion of the growth environment can refer to the unit length, the unit width, the unit height, the unit body diagonal, the unit face diagonal, the unit perimeter, the unit radius, the unit circumference, the unit surface area, the unit cross section, or the unit volume of the growth environment.

[0070] The geometry of the growth environment can be customized to support mycelium growth at several spatial scales. In some embodiments, the volume of the growth environment can fall within a range of between about at least 0.1ft3 and/or less than or equal to about 500,000ft3, or can fall within a range between about at least 1.0ft3 and/or less than or equal to 250,000ft3. In some yet further embodiments, the volume of the growth environment can be about 0.1ft3, 0.2ft3, 0.3ft3, 0.4ft3, 0.5ft3, 0.6ft3, 0.7ft3, 0.8ft3, 0.9ft3, 1.0ft3, or any range therebetween. In some yet further embodiments, the volume of the growth environment can be about 250,000ft3, 300,000ft3, 400,000ft3, 500,000ft3, or any range therebetween.

[0071] A growth environment can comprise one or more sub-environments. For example, each sub-environments can be comprised of aerial mycelium at different growth stages. Examples of various growth environments and methods of growing and producing aerial mycelium may be found in International Publications WO2019099474 to Kaplan-Bie et al., WO2022235688 to Winiski et al., WO2022235694 to Carlton et al., and United States Patent Application Publication 2015/0033620 to Greetham et al., each of which contents are incorporated by reference hereto in their entirety, to the extent not inconsistent with the content of this disclosure.

[0072] “Aerial mycelium” as used herein refers to mycelium that may be obtained from extra-particle aerial mycelial growth, and which is substantially free of growth matrix or substrate (e.g. that part of mycelial growth that extends away from and apart from a substrate or growth matrix).

[0073] “Mature mycelium” as used herein refers to mycelium that is approaching the end of its growth timeline, or is at the end of its growth timeline, but is still in contact with the growth medium, growth media, or substrate (e.g. such as still being situated on a growth bed, web, net, or shelf, or in a tray).

[0074] “Extra-particle mycelial growth” (EPM) as used herein refers to mycelial growth, which can be either appressed or aerial.

[0075] “Extra-particle aerial mycelial growth” as used herein refers to a distinct mycelial growth that occurs away from and outward from the surface of a growth matrix. Extra-particle aerial mycelial growth can exhibit negative gravitropism. In a geometrically unrestricted scenario, extra-particle aerial mycelial growth could be described as being positively gravitropic, or neutrally gravitropic, aerial, and radial in which growth will expand in all directions from its point source. In some embodiments, external forces, such as airflow, can be applied towards (e.g., approximately perpendicular to the growth environment floor) the growth substrate, and in some embodiments, through the growth substrate, for example, to create downward aerial mycelium growth in the direction of gravity. Alternatively, airflow can be applied across the growth substrate in a manner parallel or horizontal to the growth substrate surface.

[0076] “Positive gravitropism” as used herein refers to growth that preferentially occurs in the direction of gravity.

[0077] “Negative gravitropism” as used herein refers to mycelial growth that preferentially occurs in the direction away from gravity. As disclosed herein, extra-particle aerial mycelial growth can exhibit in one embodiment negative gravitropism. Without being bound by any particular theory, this may be attributable at least in part to the geometric restriction of the growth format, wherein an uncovered tool (or carrier support structure) having a bottom and side walls contains a growth matrix. With such geometric restriction, growth will primarily occur along the unrestricted dimension(s), which in the scenario is primarily vertically (negatively gravitropic).

[0078] “Growth run” or “run” as used herein refers to the time period under specific environmental conditions during which a mature mycelium is formed. In some embodiments, a growth run or run can be synonymous with or comprise of incubating. Aerial mycelia of the present disclosure can be grown in a matter of weeks or days. In some embodiments, a growth run is of a duration between about 10 days and 164 days, alternatively between about 10 days and 14 days. This feature is of practical value in the production of food ingredient or food product, where time and efficiency are at a premium. Accordingly, the presently disclosed method of making an aerial mycelium comprises incubating a growth matrix in a growth environment for an incubation time period of up to about 3 weeks. In some embodiments, the incubation time period can be within a range of about 4 days to about 17 days. In some further embodiments, the incubation time period can be within a range of about 7 days to about 16 days, within a range of about 8 days to about 15 days, within a range of about 9 days to about 15 days, within a range of about 9 days to about 14 days, within a range of about 8 to about 14 days, within a range of about 7 to about 13 days, or within a range of about 7 to about 10 days. In some more particular embodiments, the incubation time period can be about 7 days, about 8 days, about 9 days, about 10 days, about 11 days, about 12 days, about 13 days, about 14 days, about 15 days or about 16 days, or any range therebetween.

[0079] Advantageously, incubating a growth matrix comprising a colonized substrate (wherein said colonized substrate comprises a growth medium previously colonized with mycelium of a fungus) in a growth environment of the present disclosure can result in earlier expression of aerial mycelial tissue compared to incubation of a growth matrix comprising substantially the same or a similar growth medium and a fungal inoculum, wherein the fungal inoculum contains a fungus. Accordingly, a method of making an aerial mycelium of the present disclosure can comprise incubating a growth matrix comprising a colonized substrate (wherein said colonized substrate comprises a growth medium previously colonized with mycelium of a fungus) in a growth environment for an incubation time period, and producing extra-particle aerial mycelial growth therefrom, wherein the incubation time period is at least about 1 day, at least about 2 days, at least about 3 days, or at least about 4 days less than the incubation time period for producing extra-particle aerial mycelial growth from a growth matrix comprising a growth medium and a fungal inoculum, wherein the fungal inoculum comprises a fungus.

[0080] In some other embodiments, the incubation time period ends no later than when a visible fruiting body forms. In a non-limiting example, the incubation time period can end prior to a karyogamy or meiosis phase of the fungal reproductive cycle. In some other embodiments, the incubation time period ends when a visible fruiting body forms. As disclosed herein, aerial mycelia of the present disclosure can be prepared without the formation of a visible fruiting body, thus, in some embodiments, an incubation time period can end without regard to the formation of a visible fruiting body. Trial incubation runs can be used to inform the period of time in the growth environment during which sufficient extra-particle aerial mycelial growth product occurs (e.g., aerial mycelial growth of a predetermined thickness) without the formation of visible fruiting bodies.

[0081] In some embodiments, a method of making or growing an aerial mycelium of the present disclosure can comprise periodically monitoring the growth/morphology of aerial mycelium at various growth stages, and/or controlling certain aspects of a growth environment, including gas content, atmospheric pressure, temperature (such as air or substrate temperature), relative humidity, mist levels, mist composition, mist direction, lighting, provided nutrients in the form of mist and/or substrate, and nutrient and inert substrate (or growth matrix) content, in response to various monitor readings and aerial mycelium morphology.

[0082] “Mycelium-based” as used herein refers to a composition substantially comprising mycelium.

[0083] “Deviant morphology” as used herein refers to an undesired mycelium morphology. In some embodiments, deviant morphology can be morphology that departs from desired or expected morphology. For example, a desired morphology can be one that includes predetermined aesthetic properties, physical properties, hepatic properties, flavor properties, color properties, or any other desired property of a mycelium. For example, a desired morphology can have a desired tensile strength, a desired flavor profile, a desired texture, a desired density, etc. In some further embodiments, a deviant morphology can be different from a desired morphology because the physical characteristics of the deviant morphology are unsuitable for further growth or use. For example, a deviant morphology can be unsuitable or undesired as a product or intermediate product, or a deviant morphology can be unsuitable or undesired because it has not yet met its targeted or expected growth or growth trajectory for the time it has been growing in a growth environment. In some further embodiments, deviant morphology can be “permanent” or “temporary.” Permanent deviant morphology can comprise morphological properties that make a mycelium entirely unsuitable or undesired for use, and/or unamenable to repair or modification through changes in growth conditions. For example, permanent deviant morphology can comprise substantially non-contiguous growth areas, morphological malformations caused by contamination events (e.g., from other fungal strains or other biological organisms), or any combination thereof. Temporary deviant morphology can comprise morphological properties that can relate to mycelium, or part thereof, immaturity, and/or delayed growth. Such temporary deviant morphology may be mitigated within a suitable growth timeline by changes to environmental conditions. For example, temporary deviant morphology can include repairable immature growth or development at a particular stage of mycelium growth within a growth timeline. Such immature growth or development can be the result of, e.g., inconsistent application of nutrients in either the mist or substrate, or heterogeneous environmental conditions. For example, heterogenous growth conditions can include uneven mist levels across portions of the growth environment or uneven air flow or air flow rates.

[0084] “Homogeneous” as used herein refers to the topology of growth of the aerial mycelium. In some embodiments, aerial mycelium is morphologically composed of variably expressed structures (e.g., bulbous structures) with varying degrees of diffusion within and between one another, and in height, with respect to each other. This may be referred to more generally as the “topology of growth,” “growth topology” or “surface topology.” The variable and eccentric expression of bulbous features and variable tissue density within and between bulbous features represents a challenge for example, in textiles applications. For example, tensile failure can selectively occur when morphological “bulb”-forms become too discrete, due to a lack of cross-linking at the intersections between these forms, which can lead to variable failure modes and reduced physical strength. Conversely, increased homogeneity can increase tensile strength, for example, by increasing cross-linking.

[0085] “Lifecycle” as used herein refers to the developmental stages that fungi undergo, encompassing both sexual and asexual reproduction. For example, this process can involve distinct phases such as spore germination, hyphal extension, mycelial vegetative growth, formation of aerial mycelium/a, and/or the formation of specialized structures for reproduction.

[0086] “Solid-state fermentation” as used herein refers to a process wherein one or more organisms are grown on a solid substrate or solid particulate substrate. For example, this process can involve a mycelium growing between and/or within the empty spaces of the solid growth matrix or substrate, thereby providing a solid physical support for growth. “Liquid-state fermentation” as used herein refers to a process wherein one or more organisms are grown on a liquid substrate. For example, this process can involve a mycelium growing within or on the surface of a liquid growth matrix, liquid substrate, or nutrient broth.

[0087] “Casing Layer” as used herein, refers to a layer of organic or inorganic material placed on top of or below a patterning of spawn. A casing layer can be made of, for example, vermiculite, peat moss, coconut coir, any material that can be used as an uninoculated substrate, or a combination of such materials. A casing layer can be included above or below a patterning of spawn or both above and below a patterning of spawn. In some embodiments a casing layer can serve as a means for controlling the topology of an aerial mycelium. A casing layer and homogeneous aerial mycelium growth methods are described further in International Patent Publication WO2023172696 to Snyder et al., which is incorporated by reference hereto in its entirety, to the extent not inconsistent with the content of this disclosure.

[0088] The invention of the present disclosure relates at least to a heat exchanger apparatus (and variations thereof), associated methods of use of the heat exchanger apparatus, and systems incorporating the same, which provide for the heating and/or cooling of adjacent system layers contained in a growth environment. In alternative embodiments, structural variations of the heat exchanger apparatus impart secondary structural benefits to adjacent system layers, or the ability to grow additional horticultural products within the apparatus body itself. Based on the design of an inflatable bladder main body portion of the heat exchanger apparatus, it may be used in a number of previously-established growth system designs, and can be used numerous times, being easily capable of installation and removal. Further, the lower cost and lighter materials of construction allow for investment of potentially limited capital in such equipment, to provide greater control on horticultural product growth conditions by more users, at early and critical growth stages of horticultural crops.

[0089] Fig. 1 illustrates a schematic/representational view of a heat exchanger apparatus system 10 in accordance with the invention. As seen in Fig. 1, a growth environment 11 is provided (e.g. a generally enclosed or controlled environmental space, which is at least in part, isolated from surrounding environment conditions) which includes at least one carrier structure or rack 12 which includes at least two shelves 14, 16. The shelves 14, 16 of the rack 12 include separated open rails 17 for supporting various layers thereupon, for growing a horticultural product, and in one embodiment, aerial mycelium. Alternatives to the illustrated shelf design, the one or more shelves may be consecutively positioned horizontal shelves, may be comprised of solid horizontal surfaces, may include no side edges, or open rail side edges, may be comprised of wire patterns, such as grid-like wires for supporting layers, or may be a combination shelf and substrate-holding structures for example, containing cavities for holding soil (such as solid wall and bottom trays (with or without lids)). In some embodiments, the system is implemented without a shelf or tray (e.g., on another growth support structure, such as a planar support structure without side (or even bottom) walls, such as a mycological growth web, net, sideless-shelf, sideless-rack, table, or other supporting system.

[0090] In the representational view, a heat exchanger apparatus including an inflatable bladder main body 60 having feeder conduit 70 (for filling the inflatable bladder main body with a temperature-controlled fluid), supports an upper and adjacent layer of substrate, such as for example, inoculated substrate 30 which has been inoculated with fungal inoculum. The substrate is part of a solid-state fermentation system. The inflatable bladder main body 60 is situated in the drawing, directly upon the shelf open rails 17, but need not be so. In alternative embodiments, the inflatable bladder main body 60 may be inserted into rail shelving with side edge rails (as shown in Fig. 1C for example), or may be placed in perforated or non-perforated trays (as shown in Fig. 1A for example), or may be placed upon a merely flat, table-like structure, that is either a solid or perforated material (as shown in Fig. 1Q for example). Alternatively, it may be situated on a net or web, such as for ease of movement. The inoculated substrate may include various sized solid particulates (as shown as 31 in Fig. 1E for example), and may also include other nutritional components and moisture, sufficient to support the growth of mycelium or other horticultural product in a growth environment as the case may be in a growth medium (under appropriate environmental growth conditions for the particular horticultural product desired).